For over two decades, Ventilair Engineers Pvt. Ltd. (VEPL) has been at the forefront of water and wastewater treatment innovation. One of our most proven and versatile technologies is what the industry now calls the Hybrid ETP (Effluent Treatment Plant)—a solution we have mastered and delivered since the late 1990s under the earlier names: Mix Biological Treatment Plant and ETP-cum-STP Plant.

Today, the Hybrid ETP has earned its name by doing exactly what the word “hybrid” implies: combining the best of two systems—ETP and STP—into one powerful, compact, and flexible unit.

What is a Hybrid ETP?

A Hybrid ETP is a combination of an Effluent Treatment Plant (ETP) used in industries and a Sewage Treatment Plant (STP) used for domestic wastewater. This hybrid system is designed to treat both industrial effluents and domestic sewage simultaneously, within the same treatment line or setup.

It’s especially useful for manufacturing units, industrial townships, or facilities where both types of wastewaters are generated—and where space, cost, or operational efficiency demand a unified solution.

VEPL’s Legacy in Hybrid Treatment Technology

Back in the 1990s, VEPL began offering what we called a Mix Biological Treatment Plant or ETP-cum-STP, designed to deliver both biological and chemical treatment in a single plant, with FRP coting inside the Ms tanks to save rust & corrosion & lifespan of the plant.

Why FRP Coating Is Critical in Hybrid ETPs

One of the most critical design practices that ensures durability and long-term performance of a Hybrid ETP is the use of FRP (Fiber-Reinforced Plastic) coating on all MS (Mild Steel) components, especially in the primary treatment section.

During the primary treatment stage, wastewater is mixed with chemicals such as coagulants, flocculants sediments & pH adjusters, and more inside MS tanks or mixing chambers. These chemicals are often corrosive and can quickly damage untreated steel surfaces.

VEPL’s Solution:

At VEPL, we ensure that all MS tanks, mixing chambers, dosing tanks, and sludge beds are internally coated with FRP. This provides:

- Corrosion resistance against aggressive chemicals

- Extended lifespan of tanks and plant structure

- Improved hygiene and safety

- Lower long-term maintenance costs.

- Rust and corrosion

- Reduced plant life

- Frequent maintenance and downtime

- Leaching of metal ions into treated water (non-compliance risk)

It’s one of the key reasons our plants stay operational and efficient for 10+ years with minimal repairs.

Over time, as the industry matured and the demand for multi-functional, space-saving systems increased, this dual-purpose technology evolved into what is now widely known and accepted as the Hybrid ETP.

Today, VEPL is proud to be one of India’s earliest adopters and most experienced manufacturers of this advanced technology, with hundreds of installations across sectors like:

- Pharmaceuticals

- Food & Beverage

- Automobile Workshops

- Packaging Industries

- Hospitals & Hotels

- Residential-Industrial Mixed-Use Projects

Why Choose a Hybrid ETP?

Here’s why industries are increasingly switching to Hybrid ETPs:

Dual Treatment Capability

- Treats both industrial effluent and domestic sewage in a single, compact setup.

Optimized Design

- Uses a combination of physicochemical, biological, and tertiary treatments to ensure high-quality output.

Water Reuse-Ready

- Final treated water can be reused for gardening, flushing, cooling towers, or safely discharged.

Compact & Cost-Efficient

- Reduces space requirement, civil cost, and operational complexity.

Regulatory Compliance

- Designed to meet stringent CPCB and SPCB norms.

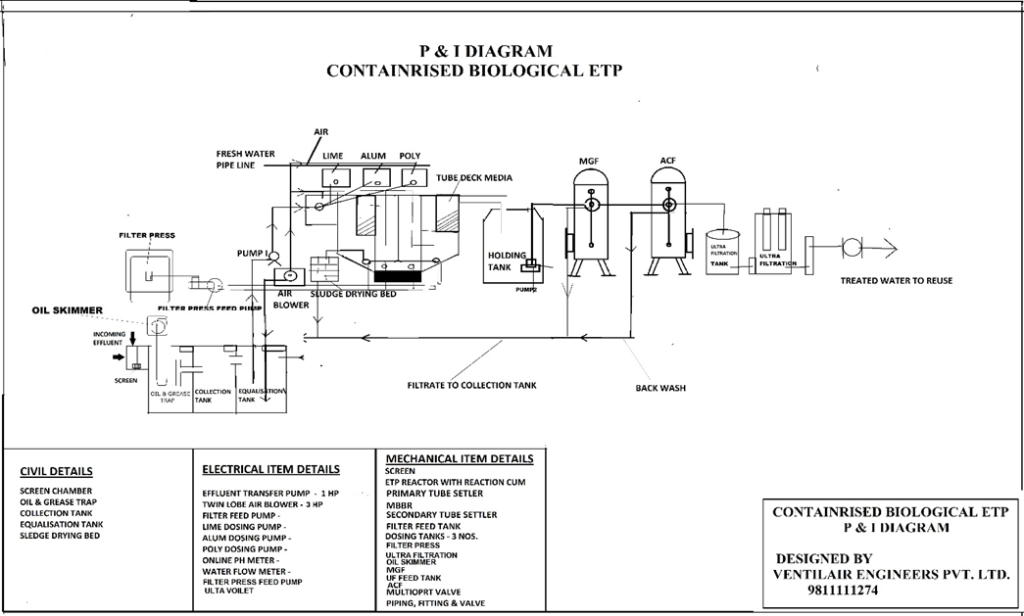

Typical Process Flow of a Hybrid ETP:

- Equalization Tank

- Chemical Dosing & Coagulation

- Primary Settling (Tube settler)

- Biological Treatment (Aeration, MBBR/SBR)

- Secondary Clarification (Tube settler)

- Filtration & Disinfection

- (Optional) Ultra Filtration for reuse applications

Real-World Success

Over the last 25 years, VEPL (Ventilair Engineers Pvt Ltd) has installed more than 300 of hybrid treatment systems across India. Our clients trust us for delivering robust, low-maintenance, and custom-designed plants tailored to their industry type, wastewater load, and site conditions.

Conclusion

Just like a Hybrid car combines the old and the new for better performance, a Hybrid ETP brings together industrial and domestic wastewater treatment technologies to create a smarter, more sustainable solution. and built to last, thanks to critical design elements like FRP-coated MS tanks.

At VEPL, we don’t just build plants—we deliver long-term performance, compliance, and water sustainability. Whether you call it a Mix Biological Plant, ETP-cum-STP, or Hybrid ETP, we’ve been mastering it since day one.

Let us help you Save, Treat & Reuse Water—because your wastewater deserves more than just basic treatment.

- #HybridETP

- #ETPcumSTP

- #MixBiologicalPlant

- #EffluentTreatmentPlant

- #SewageTreatmentPlant

- #VentilairEngineers

- #WastewaterTreatment

- #SaveTreatReuseWater

- #IndustrialETP

- #WaterRecycling