ASP-Based Sewage Treatment Plant (Activated Sludge Process)

Robust and Reliable Wastewater Treatment by VEPL

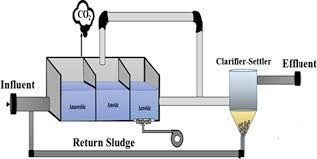

The Activated Sludge Process (ASP) is a biological wastewater treatment method that uses aerobic microorganisms to break down and stabilize organic pollutants in sewage. In this system, air (oxygen) is continuously supplied to an aeration tank containing sewage and microorganisms, which digest the organic matter. The mixture, known as mixed liquor, is then allowed to settle in a clarifier, separating clean water from sludge.

VEPL’s ASP-Based Sewage Treatment Plant is designed for high-load and long-term applications, delivering CPCB-compliant treated water ideal for reuse or safe discharge.

VEPL’s ASP-based STP is a time-tested, high-capacity wastewater treatment solution ideal for:

Large residential colonies

- Government institutions

- Industrial estates

- Commercial complexes

- Hospitals and public sector units

ASP is known for its high efficiency in BOD/COD removal, stable process control, and custom scalability for sewage flows ranging from 50 KLD to several MLD.

Process Flow & Components

Stage | Description |

Screening Chamber | Removes debris, plastics, and grit |

Equalization Tank | Regulates flow and shock loads |

Aeration Tank | Blowers inject oxygen; bacteria oxidize BOD/COD |

Secondary Clarifier | Settles activated sludge and separates clean water |

Sludge Recirculation | Returns part of the sludge to the aeration tank |

Excess Sludge Handling | Sent to sludge drying beds or filter press |

Tertiary Treatment | Sand filter + carbon filter + UV or ozonator |

Treated Water Tank | Stores water for reuse in flushing, gardening, etc. |

Control Panel | PLC/semi-auto system with blower and pump controls |

Technical Specifications

Parameter | Specification |

Technology | Conventional Activated Sludge Process |

Capacity | 50 KLD – 5 MLD (Modular design available) |

Recycle Options | Flushing, cooling tower, landscaping |

Sludge Handling | Filter press / drying beds / decanter |

Automation | Manual / Semi-automatic / PLC-based |

Treatment Process & Parameters

- Primary Treatment

(Screening, Oil & Grease Removal, Equalization)

Parameter | Inlet (Raw Sewage) | Outlet (After Primary) |

pH | 6.5 – 8.5 | 6.5 – 8.5 |

BOD | 200 – 350 mg/L | 150 – 200 mg/L |

COD | 400 – 600 mg/L | 250 – 400 mg/L |

TSS | 150 – 300 mg/L | 100 – 150 mg/L |

Oil & Grease | 20 – 50 mg/L | < 20 mg/L |

- Secondary Treatment

(Biological Treatment – MBBR/FAB/SBR + Clarifier)

Parameter | Inlet (From Primary) | Outlet (After Secondary) |

BOD | 150 – 200 mg/L | < 30 mg/L |

COD | 250 – 400 mg/L | < 100 mg/L |

TSS | 100 – 150 mg/L | < 30 mg/L |

Ammonia (NH₄) | 15 – 30 mg/L | < 10 mg/L |

Odor | Present | Mild/Neutralized |

- Tertiary Treatment

(Sand Filter + Activated Carbon Filter + UV/Chlorination)

Parameter | Inlet (From Secondary) | Outlet (After Tertiary) |

BOD | < 30 mg/L | < 10 mg/L |

COD | < 100 mg/L | < 30 mg/L |

TSS | < 30 mg/L | < 5 mg/L |

Pathogens | Present | 90–99% Removed |

Color & Odor | Slight / Off | Clear & Odor-Free |

- After Ultrafiltration (UF) – Optional Final Polishing

Parameter | Inlet (From Tertiary) | Outlet (After UF) |

BOD | < 10 mg/L | < 5 mg/L |

TSS | < 5 mg/L | < 1 mg/L |

Turbidity | < 5 NTU | < 1 NTU |

Pathogen Removal | ~99% | 99.99% |

Water Quality | Non-potable reuse | Reuse for gardening, flushing, cooling ✅ |

Power Requirement (Approximate)

Capacity | Power (HP) | Key Components |

50 KLD | ~10–12 HP | 2–3 HP blower, 2 HP pump, 1.5 HP UV, sludge pump |

100 KLD | ~18–20 HP | 5 HP blower, 4 HP pump, 2 HP UV, filter press |

250 KLD | ~30–35 HP | Multiple blowers, pumps, recirculation system |

Standby blower and pump included for uninterrupted operation.

Bacterial Treatment

- Process: Aerobic oxidation using naturally grown bacteria

- Enhancement: EM solution or bio-culture dosing (optional for startup)

- Sludge Management: Regular disposal as per PCB norms

Key Features

- Proven, reliable performance over decades

- Consistent effluent quality under variable loads

- Simple O&M – ideal for semi-skilled operators

- Long service life of all components

- Easily expandable for future load growth

- Can be upgraded to ZLD with tertiary treatment

Best Suited For

- Municipal and Government Institutions

- Industrial Townships and PSUs

- Railway Stations, Bus Terminals, Airports

- Residential Townships and Smart Cities

- Educational Campuses and Military Bases

Compliance & Certifications

- CPCB / SPCB Discharge Norms

- ISO 9001:2015 Certified System

- NGT & MoEF Guidelines

- Supports RERA, AMRUT, and Swachh Bharat Projects

Partner with VEPL for a robust and time-tested ASP-based STP that meets your current and future wastewater management needs.