Bio-Digester Based Sewage Treatment Plant (STP)

An Advanced Anaerobic Wastewater Treatment Solution by VEPL

A Bio-Digester Based Sewage Treatment Plant (STP) is a biological wastewater treatment system that uses specially cultured anaerobic bacteria to decompose and digest human waste and organic sewage without the need for oxygen. It operates in airtight digesters, converting organic matter into biogas and producing minimal sludge, while generating treated water suitable for non-potable reuse such as irrigation or flushing.

This technology offers a low-maintenance, eco-friendly, and decentralized solution for managing domestic sewage, especially in rural areas, hospitals, institutions, and off-grid locations.

VEPL offers a robust and low-maintenance Bio-Digester Based Sewage Treatment Plant (STP), ideal for locations requiring eco-friendly, cost-effective, and decentralized sewage treatment. This system uses an anaerobic bio-digester to break down organic waste without the need for continuous power supply or complex operations, making it ideal for hospitals, institutions, rural areas, and government facilities.

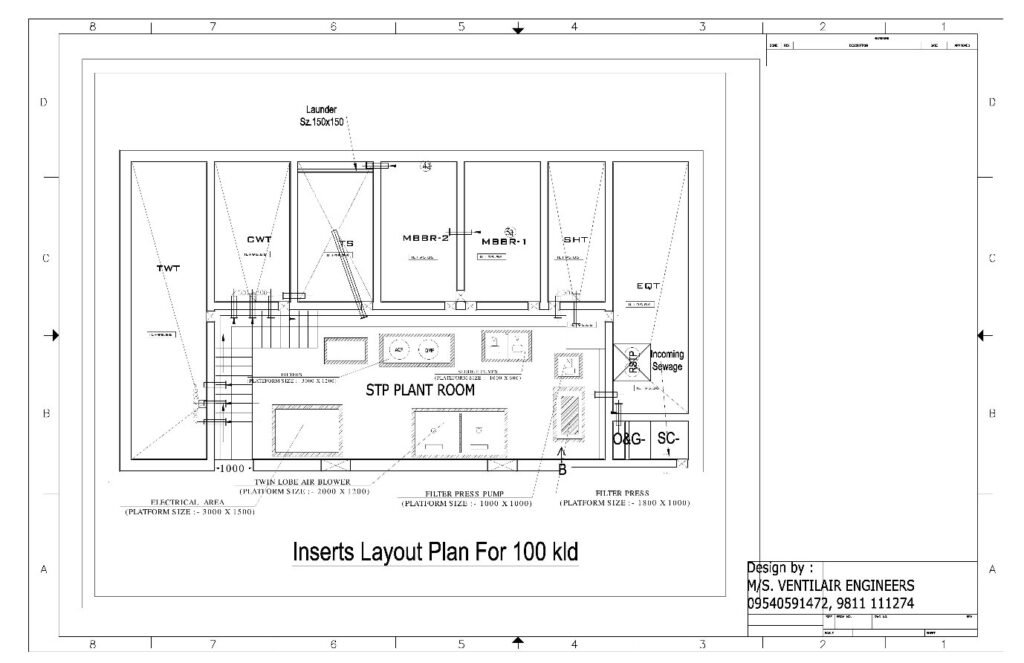

Recently, VEPL successfully installed a 100 KLD Bio-Digester STP at ESI Hospital, Kala Amb, Himachal Pradesh, serving as a benchmark in sustainable wastewater management in healthcare environments.

Technical Specifications

Component | Specification |

Treatment Capacity | 1 KLD to 250 KLD (Scalable) |

Technology | Anaerobic Bio-Digester with Optional Tertiary Treatment |

Influent BOD | 200–350 mg/L |

Effluent BOD | < 30 mg/L (can be <10 mg/L with polishing) |

Power Requirement | Very Low (Optional aeration or tertiary treatment) |

Design Type | RCC / FRP Modular Chambers |

Bio-Digester Media | Bacterial Inoculum – Psychrophilic and Thermophilic strains |

Sludge Handling | Minimal – Digested into biogas and treated water |

Odour Control | Integrated |

Life Span | >25 Years |

Operation | Semi-Automated / Manual with Training Support |

Process Flow Description

Inlet Chamber & Screening

- Removes large solids and grit

Settler/Equalization Tank

- Homogenizes sewage for stable load to bio-digester

Anaerobic Bio-Digester

- Uses specially cultured bacteria to degrade organic matter

- Produces biogas (methane + CO₂), which can be flared or utilized

Secondary Treatment (Optional)

- Clarification or Polishing Filter (Sand, Activated Carbon)

Tertiary Treatment (Optional)

- Reed Bed, UV/Chlorination for enhanced disinfection

Treated Water Outlet

- Suitable for gardening, toilet flushing, landscaping, etc.

- Treatment Process & Parameters

- Primary Treatment

- (Screening, Oil & Grease Removal, Equalization)

Parameter | Inlet (Raw Sewage) | Outlet (After Primary) |

pH | 6.5 – 8.5 | 6.5 – 8.5 |

BOD | 200 – 350 mg/L | 150 – 200 mg/L |

COD | 400 – 600 mg/L | 250 – 400 mg/L |

TSS | 150 – 300 mg/L | 100 – 150 mg/L |

Oil & Grease | 20 – 50 mg/L | < 20 mg/L |

- Secondary Treatment

- (Biological Treatment – MBBR/FAB/SBR + Clarifier)

Parameter | Inlet (From Primary) | Outlet (After Secondary) |

BOD | 150 – 200 mg/L | < 30 mg/L |

COD | 250 – 400 mg/L | < 100 mg/L |

TSS | 100 – 150 mg/L | < 30 mg/L |

Ammonia (NH₄) | 15 – 30 mg/L | < 10 mg/L |

Odor | Present | Mild/Neutralized |

- Tertiary Treatment

- (Sand Filter + Activated Carbon Filter + UV/Chlorination)

Parameter | Inlet (From Secondary) | Outlet (After Tertiary) |

BOD | < 30 mg/L | < 10 mg/L |

COD | < 100 mg/L | < 30 mg/L |

TSS | < 30 mg/L | < 5 mg/L |

Pathogens | Present | 90–99% Removed |

Color & Odor | Slight / Off | Clear & Odor-Free |

- After Ultrafiltration (UF) – Optional Final Polishing

Parameter | Inlet (From Tertiary) | Outlet (After UF) |

BOD | < 10 mg/L | < 5 mg/L |

TSS | < 5 mg/L | < 1 mg/L |

Turbidity | < 5 NTU | < 1 NTU |

Pathogen Removal | ~99% | 99.99% |

Water Quality | Non-potable reuse | Reuse for gardening, flushing, cooling ✅ |

Project Highlight:

🔹 Client: ESI Hospital, Kala Amb, Himachal Pradesh

🔹 Capacity: 100 KLD

🔹 Commissioned by: VEPL

🔹 Features:

- Compact design

- Low operational cost

- Successfully treating hospital sewage with safe water reuse

“The system has proven reliable with consistent effluent quality, reducing water footprint and ensuring regulatory compliance at ESI Hospital Kala Amb.”

Key Features & Benefits

- Eco-Friendly: Zero chemical requirement

- Energy Efficient: Works largely without electricity

- No Frequent Sludge Disposal: Sludge digested inside reactor

- Low CAPEX & OPEX: Ideal for rural or institutional setups

- Modular Design: Easy to install, expand, or relocate

- Water Reuse: Treated water fit for irrigation or reuse

Odour-Free: Proper venting and gas handling

Applications

- Hospitals & Clinics

- Schools & Hostels

- Panchayats & Rural Clusters

- Defence Establishments

- Religious Places

- Industrial Canteens

- Railway Stations

Standards & Compliance

- Ministry of Jal Shakti Guidelines

- DRDO Bio-Digester Norms (Where Applicable)

- Central Pollution Control Board (CPCB)

- Himachal Pradesh Pollution Control Board (HPPCB)

- Swachh Bharat Mission (SBM), AMRUT, Jal Jeevan Mission Compatible