CASE STUDY: Upgradation of 50 KLD ETP for Sheep Wool Dyeing Unit, Rajasthan (2016)

Project Overview

In 2016, a sheep wool dyeing unit in Rajasthan requested our support to evaluate and upgrade their existing Effluent Treatment Plant (ETP). The plant installed by a previous vendor had a very basic design and did not consider the actual pollution load from wool dyeing operations. Because of this, the unit was facing compliance problems and poor treatment performance.

Initial Observations

During the site visit, we studied the process flow and collected 1-liter representative wastewater samples for laboratory testing. The analysis showed that the effluent contained:

- Very high BOD and COD

- High suspended organic matter

- A large amount of wool fibers and hair

- High color and turbidity

- Strong odor and heavy organic load

It was clear that the existing ETP was inadequate, as it did not include any biological treatment. The unit required a combined ETP + STP type biological system to treat the organic load effectively.

Challenges Identified

- Very poor influent quality – Wastewater was extremely rich in fibers and solids; “a stick could stand in the effluent.”

- High BOD/COD, requiring a proper biological treatment stage.

- Wool fibers, causing choking and operational problems in normal systems.

- Existing ETP was only physico-chemical, resulting in low overall efficiency.

Engineering Solution

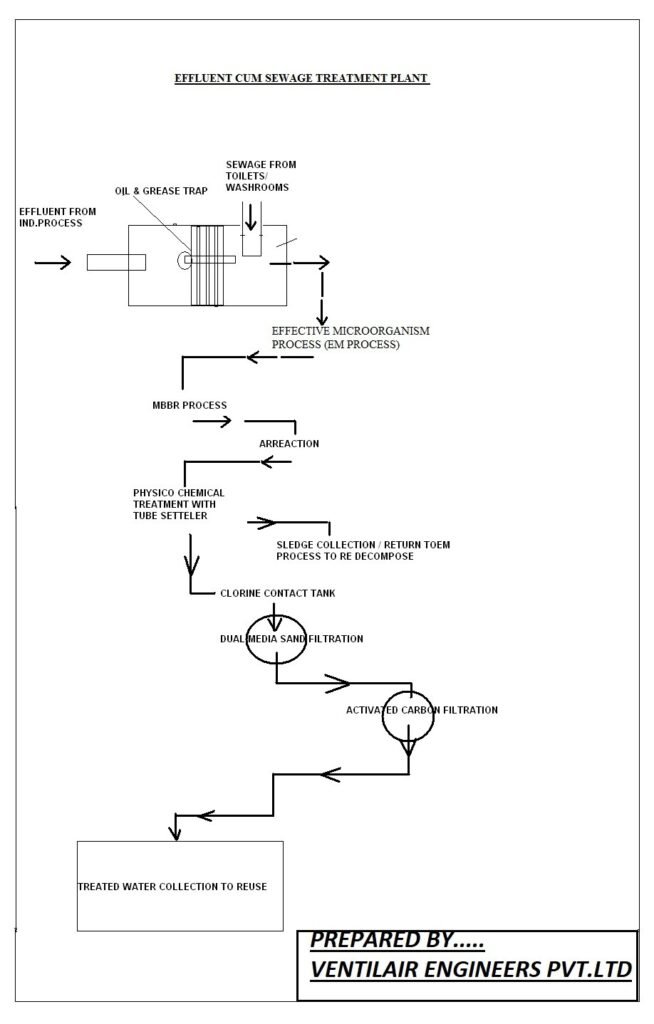

To solve these issues, we redesigned the plant into a Biological ETP (ETP-cum-STP) with an integrated treatment process.

- Pre-Treatment: Fiber & Hair Removal

- Installation of coarse screening and net-type filtration

- Prevented blockage in downstream units

- Ensured smooth operation of the entire plant

- Physico-Chemical Treatment

- Coagulation

- Flocculation

- Primary Clarification

This stage helped remove suspended solids, color, and turbidity.

- Biological Treatment (MBBR Technology)

MBBR (Moving Bed Biofilm Reactor) technology was introduced to handle the high organic load.

Key advantages of MBBR:

- High BOD/COD removal

- Stable biological activity

- Low sludge generation

- Simple operation and maintenance

- Secondary Treatment & Polishing

- Secondary settling

- Final filtration

These steps ensured the treated water met discharge norms.

Commissioning & Results

The upgraded 50 KLD ETP was successfully commissioned in 2016. After startup:

- BOD and COD reduced significantly

- Color removal improved greatly

- Wool fiber problems were almost fully eliminated

- Biological system stabilized quickly due to MBBR media

- The unit achieved consistent compliance with pollution control norms

This project has become a strong example of treating difficult wool dyeing wastewater using a combined physico-chemical and biological approach.

Improvements in Current Technology

Since 2016, our technology has further improved. For similar installations today, we now offer:

- Double Tube Settlers for improved clarification

- Advanced fibre and screening systems

- Energy-efficient aeration equipment

- Better sludge handling and dewatering options

A separate case study on Double Tube Settler applications will be shared soon.

Modern Technology Plant Image

Conclusion

This project demonstrates how an underperforming conventional ETP can be successfully upgraded into an effective biological ETP-cum-STP system. Even with highly contaminated raw wastewater, the redesigned plant performed reliably and continues to serve as a reference model for similar industries.