Containerised Sewage Treatment Plant

Compact | Modular | Plug & Play Sewage Treatment

VEPL’s Containerized Sewage Treatment Plant is an innovative, pre-fabricated, plug-and-play solution designed for quick deployment, efficient operation, and minimal civil work. Housed inside robust shipping containers, this system is ideal for temporary or permanent installations at remote sites, construction projects, institutions, and industrial zones.

Product Overview

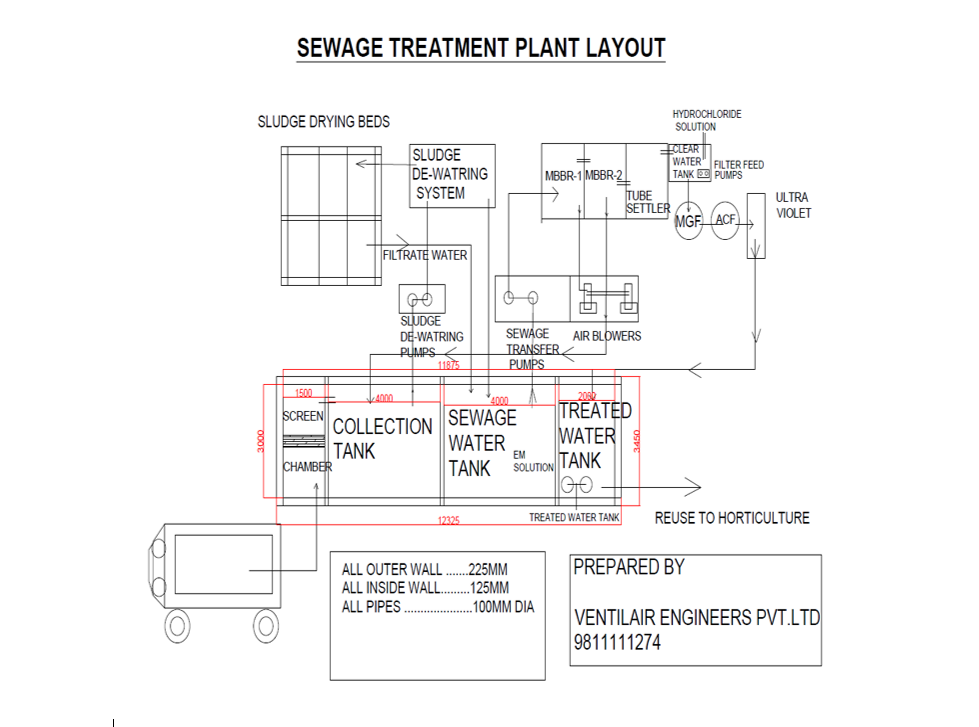

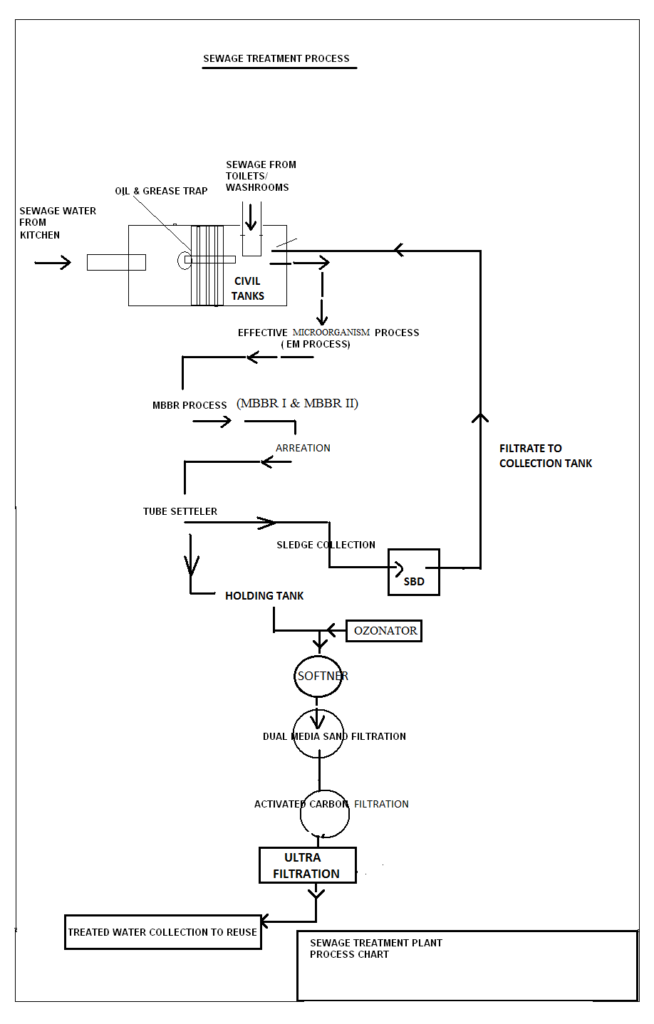

The Containerized STP is pre-engineered with all mechanical, electrical, and biological components installed within a high-grade steel container. It integrates biological treatment (MBBR or SBR), filtration, disinfection, and ultrafiltration (optional), ensuring treated water is safe for reuse or discharge.

Perfect for areas with limited space, this plant is quick to install, relocate, and scale based on your wastewater treatment requirements.

Technical Specifications

Parameter | Specification |

Treatment Capacity | 5 KLD to 500 KLD (modular design) |

Technology | MBBR / SBR / Hybrid (customized) |

Container Material | Mild Steel with anti-corrosive epoxy coating |

Container Sizes | 10ft, 20ft, 40ft ISO standard containers |

Media Type | High-efficiency biofilm carriers (for MBBR) |

Aeration System | Fine bubble diffused aeration |

Power Requirement | 2 – 15 HP (based on plant size) |

Automation | Semi-automatic / Fully automatic (PLC/SCADA) |

Mobility | Easily transportable & crane-liftable |

Installation Time | 2 – 5 Days |

Maintenance | Low O&M cost, easy servicing |

Inlet & Outlet Water Quality Parameters

Primary Treatment (Screens + Settling/Equalization)

Parameter | Inlet Range | Outlet Range |

pH | 6.5 – 8.5 | 6.5 – 8.5 |

BOD | 250 – 400 mg/L | 150 – 200 mg/L |

COD | 500 – 700 mg/L | 300 – 450 mg/L |

TSS | 200 – 350 mg/L | 100 – 150 mg/L |

Oil & Grease | 20 – 50 mg/L | < 20 mg/L |

Secondary Treatment (Biological – MBBR/SBR + Clarifier)

Parameter | Inlet | Outlet |

BOD | 150 – 200 mg/L | < 30 mg/L |

COD | 300 – 450 mg/L | < 100 mg/L |

TSS | 100 – 150 mg/L | < 30 mg/L |

Ammonia (NH4) | 20 – 40 mg/L | < 10 mg/L |

Tertiary Treatment (Sand Filter + Activated Carbon + UV/Chlorination)

Parameter | Inlet | Outlet |

BOD | < 30 mg/L | < 10 mg/L |

COD | < 100 mg/L | < 30 mg/L |

TSS | < 30 mg/L | < 5 mg/L |

Pathogens | Present | Removed (99%) |

Color/Odor | Slight | Removed |

After Ultrafiltration (Optional Final Polishing Unit)

Parameter | Inlet | Outlet |

BOD | < 10 mg/L | < 5 mg/L |

TSS | < 5 mg/L | < 1 mg/L |

Turbidity | < 5 NTU | < 1 NTU |

Pathogen Removal | Partial | 99.99% (Sterile) |

Water Reuse | Gardening, Flushing, Cooling | ✅ |

Applications

- Construction & Infrastructure Sites

- Military & Remote Camps

- Resorts, Hotels & Hostels

- Schools, Colleges, and Universities

- Factories and Industrial Areas

- Residential Colonies & Smart Cities

Key Features

- Plug & Play – Fast installation, ready to operate

- No Civil Work Needed – Fully containerized setup

- Movable & Reusable – Ideal for shifting project sites

- High Treatment Efficiency – Meets PCB discharge norms

- Low Maintenance – Minimal operator intervention

- Customizable – Add-ons: UF, MBR, RO based on reuse