Effluent Treatment Plant

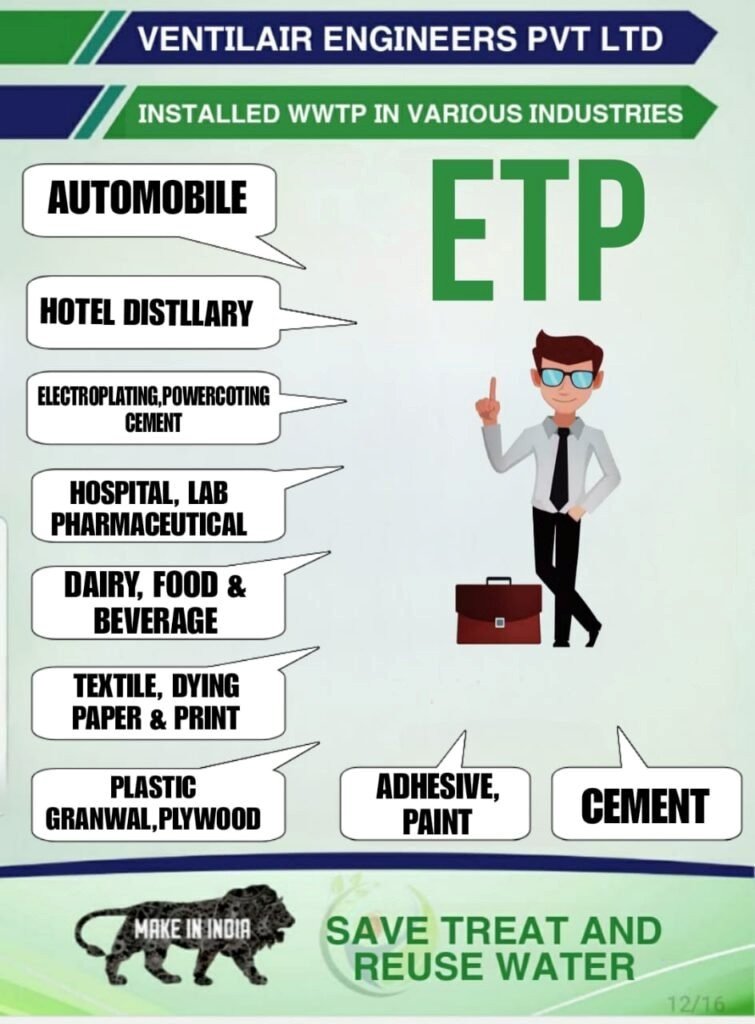

VEPL is a leading manufacturer and supplier of Industrial Effluent treatment plants which are used by different industries to reduce the potential for pollution and to comply with discharge consent conditions.

Our engineers can also custom design effluent treatment plants based on the specific requirements of the clients; first of all, the toxic components have to be removed from the wastewater flow. Physicochemical wastewater treatment is a frequently used technique in the area of wastewater treatment.

We have a huge range for effluent treatment these are

ETP for Vehicle Washing (water recycling plant)Rice Mill, Small Food Industries, Dry-Clean Industries Textile Industries, Food industries, Oil Water, Laundry, Print Industry, Seeds Rinsing, Automobile, Oils and Grease Removal, Complex Organic Chemicals Industry, Acids antalkalis, Dying Industry, Electroplating Plant, Hospital, Paper Industry, Pulp and Paper Industry,Fabric Factory, Construction Site & Various Industries,

We at Ventilair Engineers Pvt. Ltd. are known for designing and manufacturing high technology effluent treatment plant in India. With the growth in the number of industries in PAN India, the industrial waste water is rapidly increasing. Discharging such water in environment is destructive for both nature as well as living beings due to the presence of harmful substances and chemicals. With our aim to supply pure and uncontaminated water in the surrounding, we have designed best effluent treatment plant for treating all such industrial waste water.

Being into the business of waste water management for years, we follow proper methodology for effluent treatments. The availability of different industries result into the different types of effluent which requires separate treatment depending on its nature. To start with the process, our professionals first test the effluent samples to understand the kind of waste water treatment it requires. We have incorporated best technologies at Ventilair Engineers Pvt. Ltd. that are well-suited for understanding the composition of the effluents and how it can be treated. It helps us treat different types of industrial waste water and supply pure water back to the environment with ease.

Benefits of an ETP Plant:

⦁ To protect the environment from pollution

⦁ To save & reuse water.

⦁ Recycling of water

⦁ To help the increase of ground water level.

⦁ Reduces the usage of fresh water in industries

⦁ Treatment of wastewater through an effluent treatment plant

⦁ The ETP plant saves money and time.

⦁ It restores our wastewater and treats that water, which is helpful for us.

⦁ ETP eliminates the need to transport clean water.

⦁ ETP also helps in the recycling of waste that is harmful to the earth.

Wastewater Treatment Plants (WWTPs)

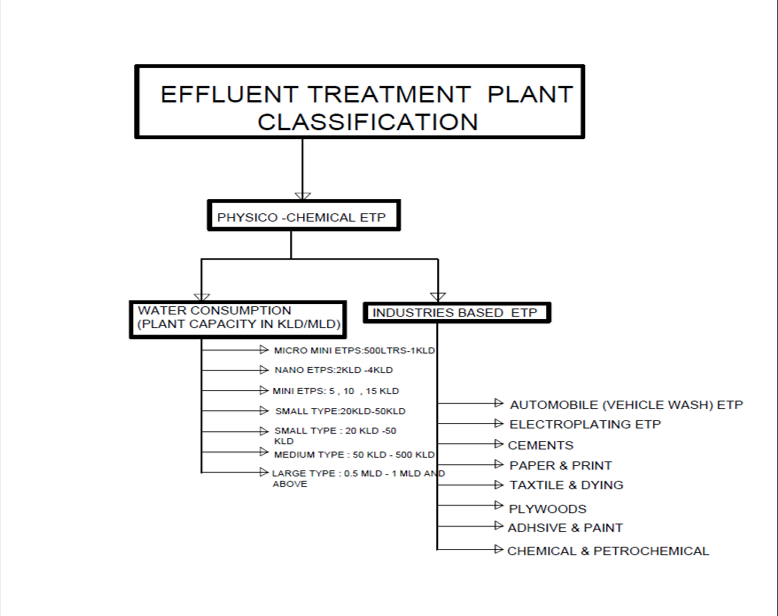

Divided into two major categories:

- Effluent Treatment Plants (ETPs)

- Sewage Treatment Plants

Effluent Treatment Plants divided into two parts

Physio-Chemical ETP

(Coagulation, Flocculation, Sedimentation, Filtration, Neutralization)

Biological/ Hybrid ETP

Aerobic Processes

Anaerobic Processes

Physio-Chemical ETP also divided into two parts

- a) Water Consumption Based ETP (Physical Parameters)

- b) Industry Based ETP

Parts of Consumption based ETP

- Micro Mini ETPs: 500LTRS -1 KLD,

- NANO ETPS: 2 KLD – 4KLD,

- MINI ETPS: 5,10,15 KLD

- Small Type: 20 KLD – 50 KLD

- Medium Type: 50 KLD – 500 KLD

- Large Type: 0.5 MLD – 1 MLD and above

b) Parts of Industry Based ETP

1 AUTOMOBILE (VEHICLE WASH) ETP

2 ELECTROPLATING ETP

4 PLASTIC GRANNULE ETP

5 CEMENTS

6 PAPER & PRINT

8 TAXTILE & DYING

9 PLYWOODS

10 ADHSIVE & PAINT

11 Chemical & Petrochemical

- b) Biological ETP / ETP cum STP

HYBRID ETP (Biological ETP)

1 ETP for Hospitals & Mortuaries

2 ETP for Commercial Kitchens & Dairy

3 Rice Mill Effluent Treatment Solutions

4 ETP for Argo & Fertilizer Industry

5 ETP FOR Pharma & Hospital

6 ETP FOR Hospitality Industry ETP

- ETP for Leather/Tannery Industry