Effluent Treatment Plant Manufacturers in Delhi

VEPL is a leading manufacturer and supplier of Industrial Effluent treatment plants which are used by different industries to reduce the potential for pollution and to comply with discharge consent conditions.

Our engineers can also custom design effluent treatment plants based on the specific requirements of the clients; first of all, the toxic components have to be removed from the wastewater flow. Physicochemical wastewater treatment is a frequently used technique in the area of wastewater treatment.

We have a huge range for effluent treatment these are

ETP for Vehicle Washing (water recycling plant)Rice Mill, Small Food Industries, Dry-Clean Industries Textile Industries, Food industries, Oil Water, Laundry, Print Industry, Seeds Rinsing, Automobile, Oils and Grease Removal, Complex Organic Chemicals Industry, Acids antalkalis, Dying Industry, Electroplating Plant, Hospital, Paper Industry, Pulp and Paper Industry,Fabric Factory, Construction Site & Various Industries,

We at Ventilair Engineers Pvt. Ltd. are known for designing and manufacturing high technology effluent treatment plant in India. With the growth in the number of industries in PAN India, the industrial waste water is rapidly increasing. Discharging such water in environment is destructive for both nature as well as living beings due to the presence of harmful substances and chemicals. With our aim to supply pure and uncontaminated water in the surrounding, we have designed best effluent treatment plant for treating all such industrial waste water.

Being into the business of waste water management for years, we follow proper methodology for effluent treatments. The availability of different industries result into the different types of effluent which requires separate treatment depending on its nature. To start with the process, our professionals first test the effluent samples to understand the kind of waste water treatment it requires. We have incorporated best technologies at Ventilair Engineers Pvt. Ltd. that are well-suited for understanding the composition of the effluents and how it can be treated. It helps us treat different types of industrial waste water and supply pure water back to the environment with ease.

At present, we are capable of dealing with multiple types of industrial effluents including oil & grease, solid particles, heavy metals, harsh chemicals, food waste, a wide variety of other organic and non-organic waste. Our effluent treatment plant focuses on all the steps that are required for treating effluents successfully. It starts from the preliminary process where the removal of oil, grease, and solid particles takes place. In the second stage, which is the primary stage, the removal of suspended solid particles, floating waste, and other organic material takes place. The third stage is quite crucial as all the biodegradable organic matter is being removed. At the end, the dissolved solid particles and residue from different types of waste and solid particles is filtered out. Once the effluent gets treated by following all the parameters, the water then gets tested for its quality and safety and is later on released in the environment.

Benefits of an ETP Plant:

⦁ To protect the environment from pollution

⦁ To save & reuse water.

⦁ Recycling of water

⦁ To help the increase of ground water level.

⦁ Reduces the usage of fresh water in industries

⦁ Treatment of wastewater through an effluent treatment plant

⦁ The ETP plant saves money and time.

⦁ It restores our wastewater and treats that water, which is helpful for us.

⦁ ETP eliminates the need to transport clean water.

⦁ ETP also helps in the recycling of waste that is harmful to the earth.

VEPL Provides Two type of Technology of Effluent Treatment Plants

Physio-chemical Biological with Physio-chemical

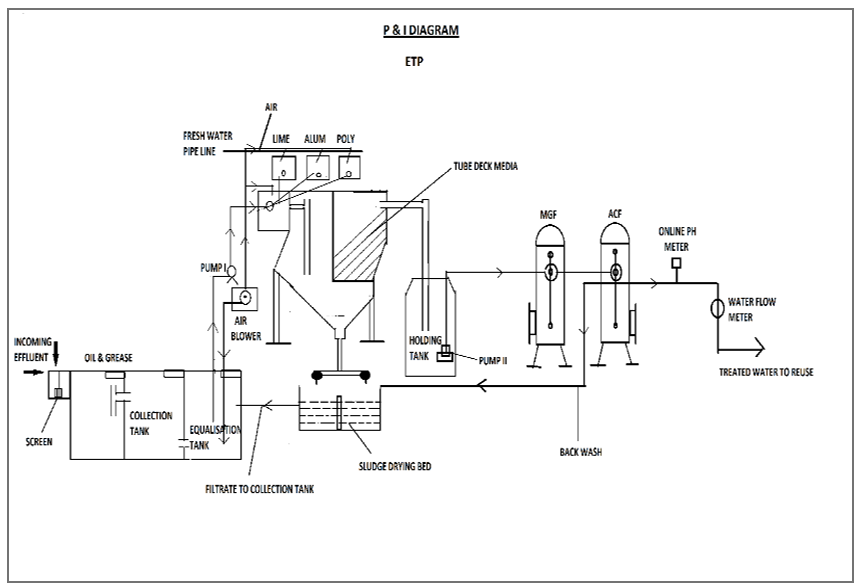

Physio-chemical Effluent Treatment Plant

The physicochemical wastewater treatment techniques are used as pre-treatment, final treatment as well as specific treatment for wastewater reuse as process water. VEPL is a leading manufacturer and supplier of The Physicochemical Effluent treatment plants for. These effluent treatment plants are used by different industries to reduce the potential for pollution and to comply with discharge consent conditions.

Separation by floatation, filtration or under gravitational influence is usually very useful for removing larger and visible contaminating particles. However, for colloidal particles which can easily filter through and have similar electrostatic surface charges which impede their coagulation, physio chemical treatment methods are more effective. Physio chemical treatment involves using chemicals which can modify physical state of colloidal particles which helps in making them more stable and coagulation for further treatment or filtration purposes. These treatment methods have been used for over a century in conjunction with biological treatment methods.

This method is applied in various Industries as Vehicle wash, Electroplating, Powder Coating, Zinc Plating, Plastic granule, Textile, Paper, Dying, Printing, Laundry, Acids & Alkalis etc….

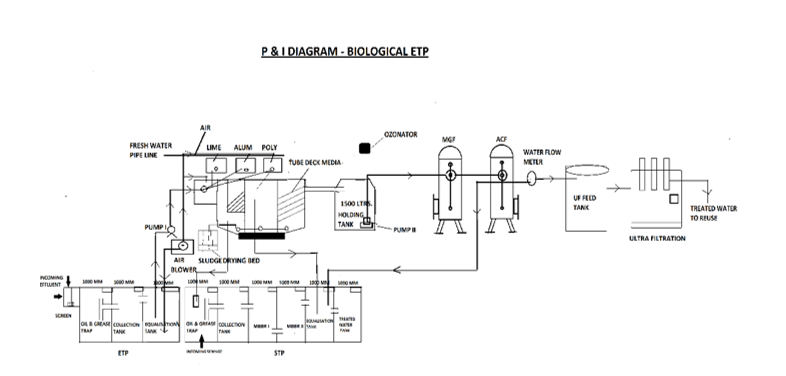

Biological with Physio-chemical(ETP Cum STP for Food Industry)

VEPL is offeringBiological with Physio-chemical(ETP Cum STP for Food Industry).The effluents produced by the food and beverage, Hospital & few industries (where Bod to be very high) are different from the municipal wastewater. These are biodegradable and non-toxic wastes that are high in concentrations of BOD and Suspended Solids. Major source of these effluents are hotels& hospitals. Our range of effluent treatment plants is manufactured by using the highest grade of raw materials and branded components.

Processing of food from raw materials requires large volumes of high grade water. Vegetable washing generates waters with high loads of particulate matter and some dissolved organic matter. It may also contain surfactants.

Backed by the vast industry experience and sound technological expertise, we are manufacturing of Biological with Physio-chemicalEffluent Treatment Plants.

We at Ventilair Engineers Pvt. Ltd. are known for offering effluent treatment plant services for multiple industries. Some of them include chemical industry, food and beverage processing industry, paper and pulp industry, pharmaceutical industry, automotive industry, mining industry, dye and pigment processing industry, fertilizer industry, oil & gas industry, leather manufacturing industry, textile industry, and municipalities.

Why choose Ventilair Engineers Pvt. Ltd. for Effluent Treatment Plant?

Ventilair Engineers Pvt. Ltd. is managing the waste water treatment business for several years from now. We are one of the leading effluent treatment plant providers in India. We adhere to all the industrial, national, and government set standards to carry out the effluent treatment smoothly. We have treated tons of effluents with the help of world-class technology and expert professionals who have been working in this industry for years. Along with taking the responsibility of treating different types of effluents, we also take complete responsibility of testing the safe water generated at the end. It helps us ensure that the water is safe to release in the environment and is suitable to reuse for several tasks.

We have become best effluent treatment plant provider by qualifying to all the parameters set by government. From constructing and installing the waste water treatment plant to successfully operating it, we take care of all. We also take complete care of the maintenance of the effluent.

treatment plant on timely basis to ensure effective operations. Our professionals are available to handle any kind of trouble shooting if required at the wastewater treatment plant. The cost of the setup of effluent treatment plants is quite nominal and is suitable for various level industries. It helps us support all the industries in managing their effluent waste in the right way. Our supervisors are there to assist one in getting complete information about our effluent treatment plants and how they are being operated.