Effluent Treatment Plants (ETP) for Commercial Kitchens & Dairy

Specialized ETP Solutions for Food & Dairy Wastewater

Processing At Ventilair Engineers Pvt. Ltd. (VEPL), we specialize in delivering compact and efficient Effluent Treatment Plants (ETPs) for restaurants, food courts, hotels, and commercial kitchens & dairy industry. These facilities generate wastewater that is rich in organic waste, oil & grease, food residues, and cleaning chemicals — making effective treatment essential for environmental safety and regulatory compliance.

We are proud to share that VEPL has successfully installed more than 175 ETPs for the restaurant and food service industry, all of which are running efficiently and meeting prescribed discharge norms.

Typical Wastewater Characteristics

From Restaurants, Hotels, and Food Courts:

- Food waste, starches, and organic solids

- High levels of fats, oils, and grease (FOG)

- Detergents, soaps, and sanitizers

- Suspended solids, foul odors, and emulsified organics

- Elevated BOD (Biochemical Oxygen Demand) and COD (Chemical Oxygen Demand)

From Dairy Processing Units:

- Milk spillage, whey, and lactose

- Wastewater from CIP (Cleaning-in-Place) systems

- Fats, proteins, and chemical residues

- Fluctuating pH and high organic load

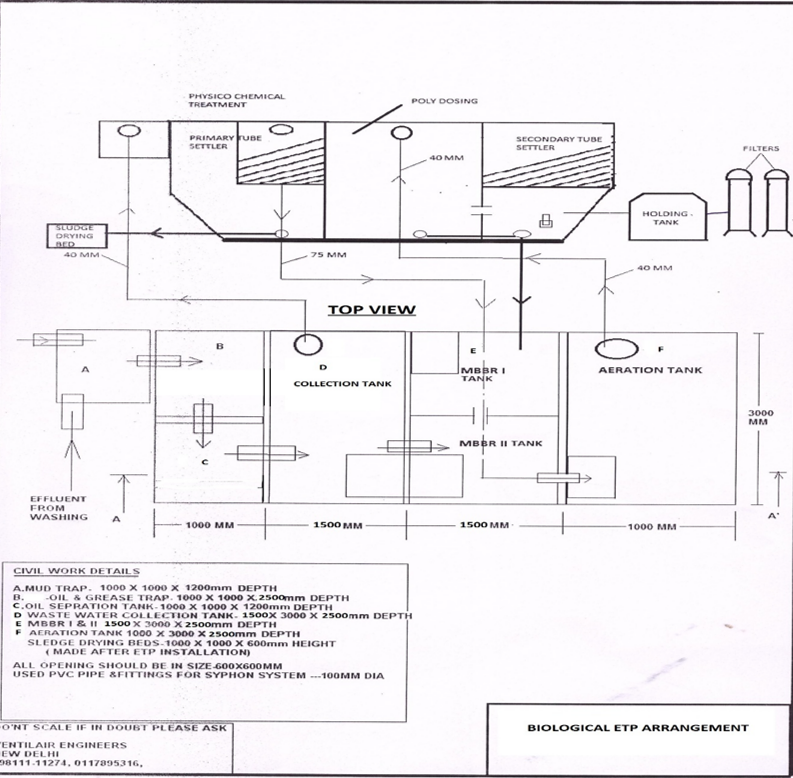

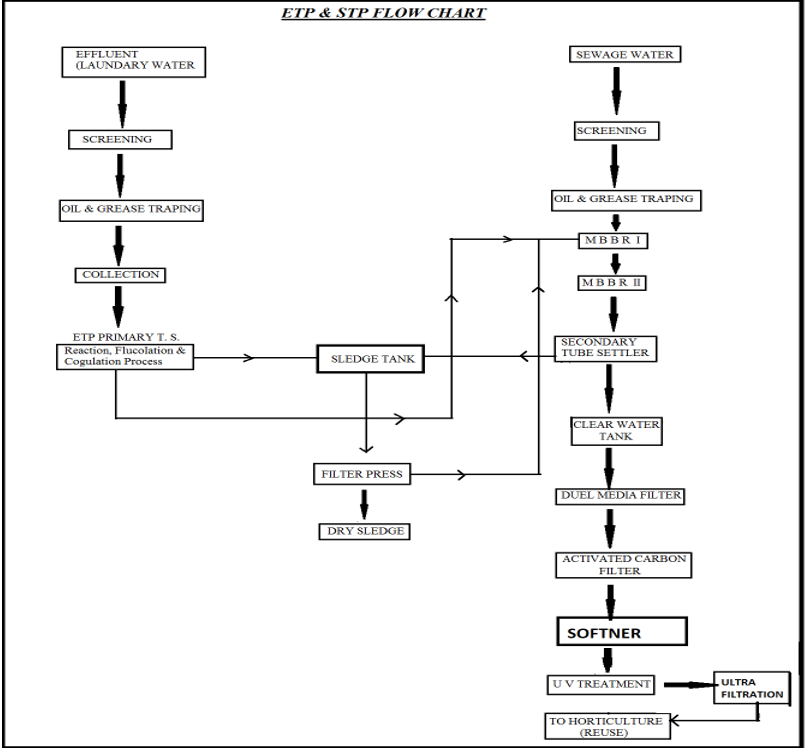

VEPL’s Proven 4-Stage ETP Process

Our modular, urban-friendly, and low-footprint systems are designed for efficient, compliant, and long-term performance.

1️ Pre-Treatment

- Oil & Grease Trap to capture fats and cooking oils

- Bar/Sieve Screening for food particles and solids

- Equalization Tank with aeration to stabilize flow and load

2️ Physio-Chemical Treatment

- pH Correction and dosing for optimal chemical conditions

- Coagulation & Flocculation to separate emulsified fats and solids

- Primary Settler or Tube Settler for effective sludge removal

3️ Biological Treatment

- MBBR (Moving Bed Biofilm Reactor) or ASP (Activated Sludge Process)

- Efficient aerobic degradation of organic pollutants

- Fine bubble diffusers and energy-efficient blowers

4️ tertiary & Polishing Treatment

- Multigrade Sand Filter (MGF) and Activated Carbon Filter (ACF)

- UV Disinfection or Chlorination for pathogen elimination

- Ultra Filtration (UF) for water reuse in toilet flushing, gardening, and floor washing

Why VEPL is the Trusted Choice

- 175+ ETPs successfully installed across India

- Custom-built compact designs for basements, rooftops, and tight urban spaces

- Expert solutions for FOG-heavy, organic-rich wastewater

- Easy-to-operate, low-maintenance systems with automation options

- Fully compliant with CPCB, FSSAI, NGT, and local drainage regulations

Where Our Plants Are Installed

- Restaurants & Cloud Kitchens

- Mall Food Courts & Cafeterias

- 5-Star Hotels & Banquet Halls

- Dairy Processing & Milk Packaging Units

- Corporate & College Canteens

- Highway Dhabas & Industrial Kitchens

- Food Manufacturing & Catering Facilities

VEPL’s Commitment to Clean, Compliant & Sustainable Operations

At VEPL, we understand the unique challenges of managing greasy, high-organic-load, and chemically treated wastewater in the food and dairy industry.

That’s why our ETPs are:

- Designed for odor-free, clog-free operations

- Equipped for water reuse and recycling

- Engineered for long-term durability and ease of use

- Built to ensure zero non-compliance with environmental norms

Over 175 commercial kitchens and dairies are already treating their wastewater the smart way—with VEPL. Join them today.