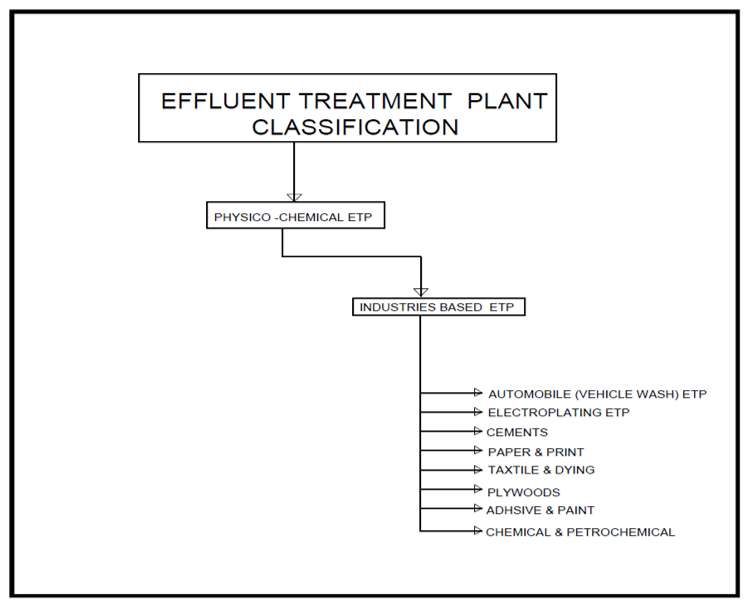

Industry Based Effluent Treatment Plants (ETPs)

At VEPL, we offer precision-engineered Effluent Treatment Plants (ETPs) designed exclusively for non-biodegradable industrial effluents that cannot be treated using biological processes. These ETPs are ideal for sectors where the wastewater contains heavy metals, toxic chemicals, surfactants, solvents, and high Total Dissolved Solids (TDS). Our industry-based ETP solutions are built to meet strict discharge norms of CPCB/SPCB while enabling maximum operational efficiency and safety.

These systems are based on advanced physico-chemical, filtration, neutralization, and separation processes, with optional tertiary and recovery units depending on application and capacity.

Ideal Industries Served with Industry-Specific ETPs

- Electroplating Industry

▪️ Treats heavy metals like chromium, nickel, zinc, and copper

▪️ Involves metal precipitation, chemical dosing, neutralization, and filtration

▪️ Includes sludge handling and heavy metal recovery options - Powder Coating & Surface Treatment

▪️ Removes pigments, phosphates, oils, and metal residues

▪️ pH adjustment, coagulation, filtration, and solid separation processes

▪️ Compact footprint; available in modular design - Automobile Component Manufacturing

▪️ Handles coolant, grease, oil emulsions, and metal fines

▪️ Skimmers, oil-water separators, chemical dosing, and filtration

▪️ Optional RO for reuse of treated water in cooling or washing - Chemical Manufacturing & Blending Units

▪️ Complex toxic and non-biodegradable effluent

▪️ Neutralization, chemical oxidation/reduction, flocculation, and clarification

▪️ Custom treatment with corrosion-resistant materials - Plastic Granule & Injection Molding Industry

▪️ Removes dyes, additives, wash water residues, and oils

▪️ Treats color, fine solids, and light organics through settling and filtration

▪️ Effluent suitable for safe discharge or reuse (optional) - Battery Water & Acid Handling Facilities

▪️ Acidic wastewater with lead, sulfuric acid, and other toxins

▪️ Multi-stage neutralization, pH balancing, and sedimentation

▪️ Special containment and corrosion-resistant construction - Cement Manufacturing & RMC Plants

▪️ Treats wash water, slurry, and process residues

▪️ Uses sedimentation, clarification, and recycling systems

▪️ Recycles treated water for mixer, cleaning, or curing applications - Thread Manufacturing & Yarn Processing

▪️ Deals with lubricants, dye carryover, and sizing chemicals

▪️ Uses flocculation, pressure filtration, and pH control

▪️ Effluent treated to remove TDS, color, and solids - Paper Processing & Packaging Units

▪️ Handles suspended solids, adhesives, and bleaching agents

▪️ Coagulation–flocculation, settling, and tertiary polishing

▪️ Optional RO or UF for reuse of treated water - Textile Auxiliary & Dye Mixing Units

▪️ Removes synthetic dyes, surfactants, alkalis, and salts

▪️ Physico-chemical treatment combined with color removal systems

▪️ High-efficiency decolorization, followed by pH balancing

Key Features of VEPL Industry-Based ETPs

- Based on physico-chemical principles: no biological treatment used

- Designed for high-toxicity, heavy metal, oil & grease, and chemical-laden wastewater

- Compact, modular, and easy-to-operate systems

- Optional automation (PLC/SCADA) for real-time monitoring

- Discharge-ready as per local pollution control board standards

- Sludge reduction & safe disposal arrangements available

Technologies Used

- Coagulation–Flocculation

- pH Neutralization Units

- Settling and Clarifiers

- Oil & Grease Removal

- Pressure Sand Filters / Carbon Filters

- Reverse Osmosis / UF (optional for water reuse)

- Sludge Dewatering Units (Centrifuge or Filter Press)

Why Choose VEPL?

Feature | VEPL Advantage |

Industry Focus | Each ETP is tailored to specific effluent load & contamination profile |

Turnkey Expertise | From design and engineering to installation & after-sales support |

Customization | Modular, space-saving designs for small to large industries |

CPCB/SPCB Compliant | Meets all discharge parameters and reporting requirements |

Affordable & Reliable | High-performance at competitive costs |

INDUSTRYWISE EFFLUENT TREATMENT PLANT

Industry-wise Effluent Treatment Plant Solutions

Customized ETPs for Every Industrial Sector

At Ventilair Engineers Pvt. Ltd. (VEPL), we understand that effluent characteristics vary significantly across industries. That’s why we offer tailor-made ETP solutions designed to meet the specific chemical, organic, and physical loads of each sector.

Below is a quick overview of how VEPL adapts its ETP design to suit different industries:

Industry | ETP Design Focus |

Textile & Dyeing | Handles high COD, color, and salt load; includes equalization, biological, ACF, RO |

Pharmaceutical | High BOD/COD, toxic compounds; advanced treatment with MBBR/MBR, tertiary polishing |

Chemical & Fertilizers | Complex pH, heavy metals; pH correction, neutralization, clarifiers, filters |

Food & Dairy | High organic load; MBBR/SBR + sludge dewatering and odor control |

Automotive & Electroplating | Heavy metals and oil; includes oil separator, chemical treatment, and polishing |

Hospitals & Labs | Pathogens, antibiotics; includes disinfection (UV/ozone), biological treatment |

Hotels & Resorts | Domestic sewage; compact SBR/MBBR with tertiary reuse-ready water |

Plastic & Recycling Units | Suspended solids, dyes; includes DAF, filters, and pH balancing |

Cement & Mining | High TSS and alkaline pH; settling, chemical dosing, and reuse options |

Educational Institutions | Sewage and canteen waste; space-saving ETPs with treated water for gardenin |

Each VEPL ETP is:

- Effluent-specific – Engineered after testing actual samples

- Modular & Scalable – Suitable for future expansion

- Reuse-Ready – For non-potable applications like flushing & gardening

- CPCB/SPCB Compliant – Discharge norms fully met