Large Capacity Sewage Treatment Plant (500 KLD to 1000 KLD & Above)

Engineered by VEPL for Smart Cities, Industries, and Institutions

VEPL’s Large Capacity Sewage Treatment Plant (STP) is a custom-engineered, high-efficiency solution for treating and recycling large volumes of domestic or industrial wastewater — ranging from 500 KLD to campuses, these STPs are designed with cutting-edge technologies including:

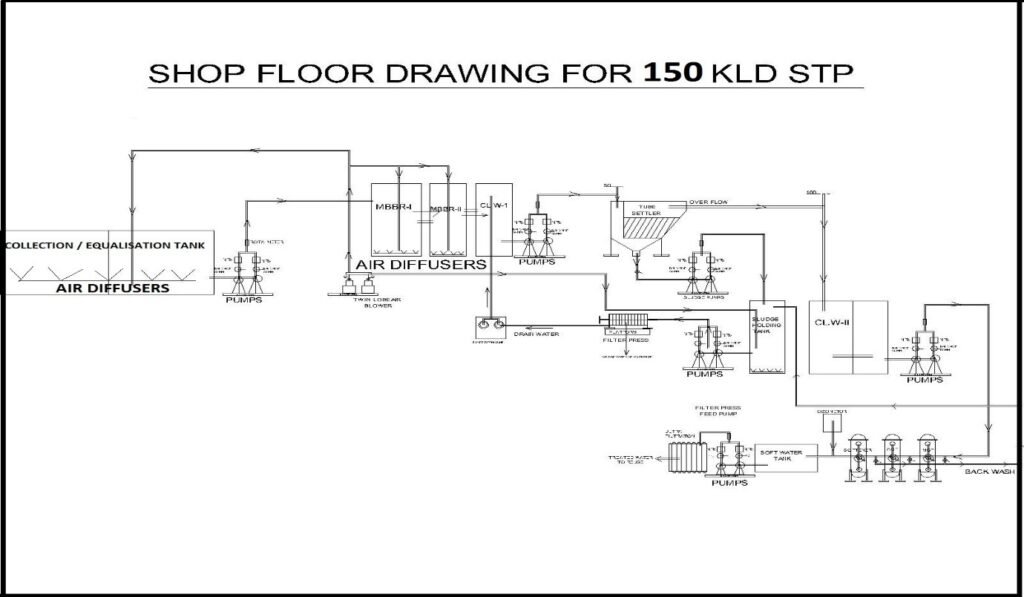

- Sequential Batch Reactor (SBR) / Moving Bed Biofilm Reactor (MBBR)

- Tertiary Treatment with Ultra-Filtration (UF), UV, and Ozonation

- Sludge Handling with Filter Press and Drying Beds

- Advanced SCADA/PLC-based automation (Optional)

Key System Components

Treatment Stage | Description |

Preliminary | Screening chamber, oil & grease trap, grit removal |

Equalization Tank | Stabilizes flow and load variations |

Biological Treatment | MBBR / SBR / ASP process using EM solution or bio-culture |

Secondary Clarifier | Settles biological sludge |

Tertiary Treatment | Sand filter + carbon filter + UF membrane |

Disinfection | UV system + Optional Ozonator |

Sludge Management | Sludge drying beds + filter press for dewatering |

Reuse Distribution | Treated water storage tank + pumps for reuse (flushing, irrigation, etc.) |

Backup | Standby pumps, blowers, and DG integration for 24×7 operation |

Technical Specifications

Parameter | Specification |

Capacity | 500 KLD to 2000 KLD+ (Modular design for higher capacity) |

Treated Water Use | Flushing, landscaping, HVAC makeup, cooling towers, construction |

Technology Options | MBBR, SBR, or Conventional ASP (depending on client/site) |

Power Supply | 3-phase, 50 Hz with energy-efficient motors |

Automation | SCADA/PLC integration available |

Structure Type | RCC, MS with epoxy coating, or hybrid (based on site) |

Estimated Power Consumption (Approximate)

Plant Size | Total Power Load | Equipment Breakdown |

500 KLD | 40–50 HP | Blowers: 15–20 HP, Pumps: 15 HP, UV/Ozone/UF: 10–15 HP |

750 KLD | 65–75 HP | Blowers: 25 HP, Pumps: 20 HP, UF/Disinfection: 20 HP |

1000 KLD | 85–100 HP | Blowers: 30 HP, Pumps: 30 HP, UF/UV/Ozone: 25–30 HP |

Standby units included for critical components (pumps, blowers, etc.)

Treatment Process & Parameters

- Primary Treatment

(Screening, Oil & Grease Removal, Equalization)

Parameter | Inlet (Raw Sewage) | Outlet (After Primary) |

pH | 6.5 – 8.5 | 6.5 – 8.5 |

BOD | 200 – 350 mg/L | 150 – 200 mg/L |

COD | 400 – 600 mg/L | 250 – 400 mg/L |

TSS | 150 – 300 mg/L | 100 – 150 mg/L |

Oil & Grease | 20 – 50 mg/L | < 20 mg/L |

- Secondary Treatment

(Biological Treatment – MBBR/FAB/SBR + Clarifier)

Parameter | Inlet (From Primary) | Outlet (After Secondary) |

BOD | 150 – 200 mg/L | < 30 mg/L |

COD | 250 – 400 mg/L | < 100 mg/L |

TSS | 100 – 150 mg/L | < 30 mg/L |

Ammonia (NH₄) | 15 – 30 mg/L | < 10 mg/L |

Odor | Present | Mild/Neutralized |

- Tertiary Treatment

(Sand Filter + Activated Carbon Filter + UV/Chlorination)

Parameter | Inlet (From Secondary) | Outlet (After Tertiary) |

BOD | < 30 mg/L | < 10 mg/L |

COD | < 100 mg/L | < 30 mg/L |

TSS | < 30 mg/L | < 5 mg/L |

Pathogens | Present | 90–99% Removed |

Color & Odor | Slight / Off | Clear & Odor-Free |

- After Ultrafiltration (UF) – Optional Final Polishing

Parameter | Inlet (From Tertiary) | Outlet (After UF) |

BOD | < 10 mg/L | < 5 mg/L |

TSS | < 5 mg/L | < 1 mg/L |

Turbidity | < 5 NTU | < 1 NTU |

Pathogen Removal | ~99% | 99.99% |

Water Quality | Non-potable reuse | Reuse for gardening, flushing, cooling ✅ |

Biological Treatment Media

- Type: High-surface-area MBBR media or batch-activated sludge

- Inoculation: EM Solution / Commercial Bacterial Culture

- Advantages: Faster start-up, stable performance under load fluctuations

- Sludge Handling: Sludge dewatering through filter press and disposal as per PCB norms

Key Advantages

- Designed for 100% Reuse – Complies with Zero Liquid Discharge (ZLD) policies

- Automation-Ready – SCADA/PLC-enabled for remote monitoring

- Reliable Operation – Engineered for continuous duty with built-in redundancy

- Regulatory Compliant – CPCB, NGT, and state PCB approved discharge norms

- Long Lifespan – Heavy-duty construction for 20+ years of operation

- Expandable – Modular configuration for phased growth

Applications

- Smart Cities & Municipal Townships

- IT Parks, SEZs, & Industrial Clusters

- Airports, Rail Terminals, & Stadiums

- Mega Housing Projects & Mixed-Use Developments

- Universities, Defense Zones, & Hospitals

- Construction Camps & Infrastructure Projects

Certifications & Standards

- CPCB & SPCB Compliant

- ISO 9001:2015 Certified System Design

- RERA, NGT, and MoEF Guidelines Compliance

- Green Building Norms & IGBC Criteria Support