Leather & Tanneries Biological ETP

VEPL’s Hybrid ETP System – For Tannery Wastewater

Hybrid Effluent Treatment Plant (ETP)

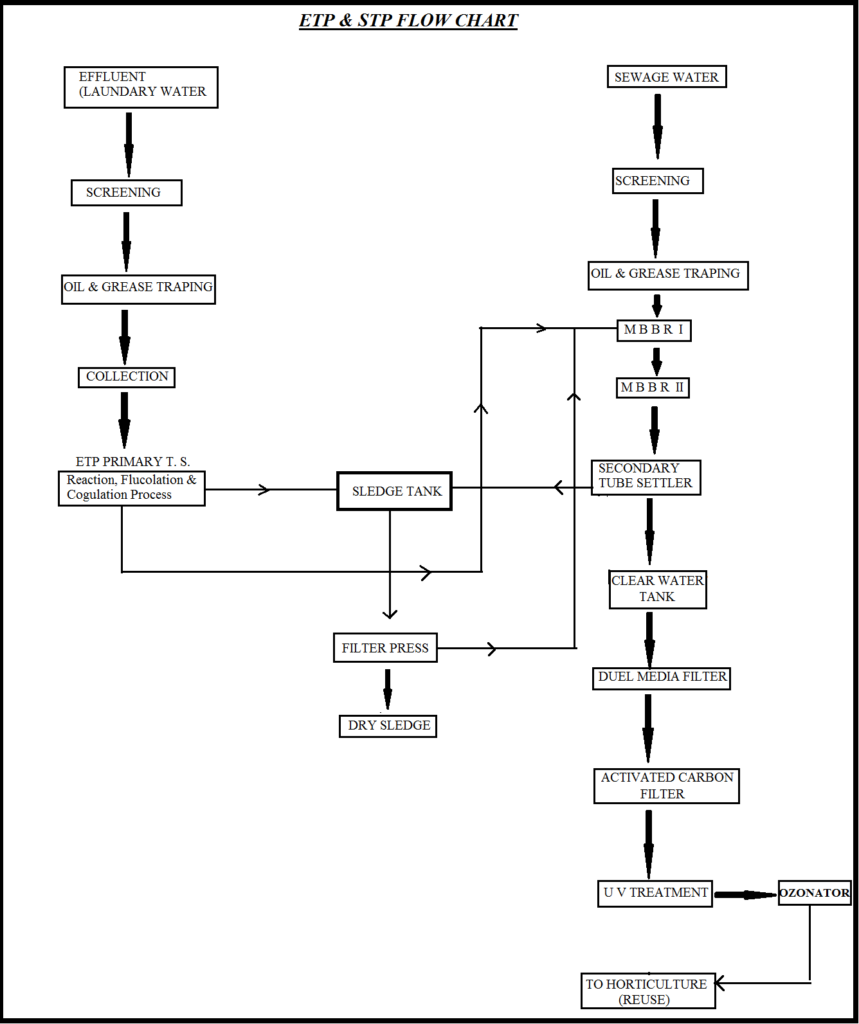

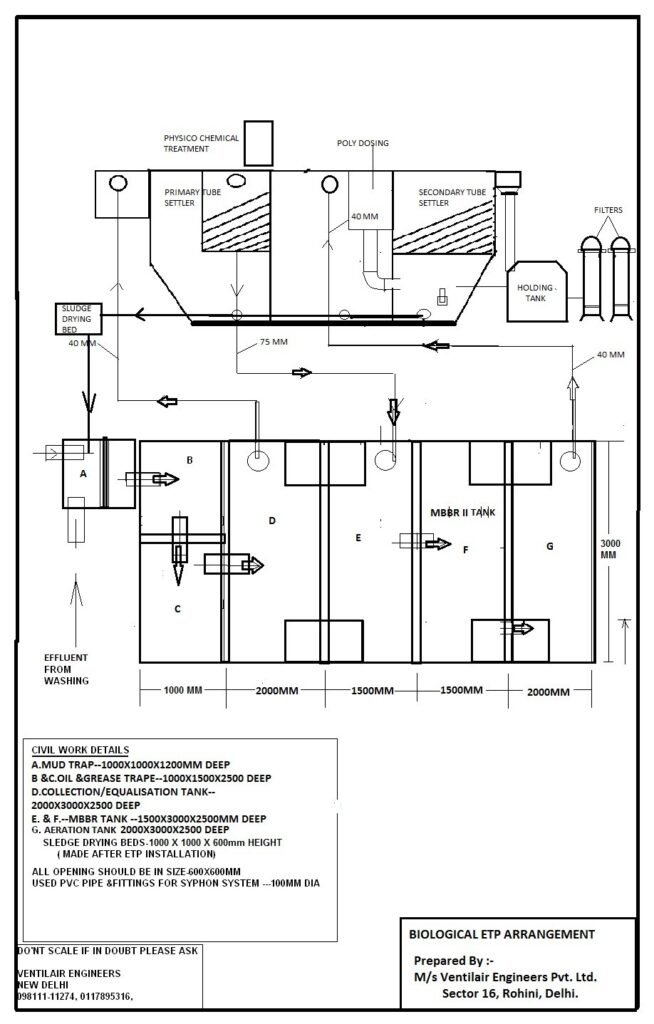

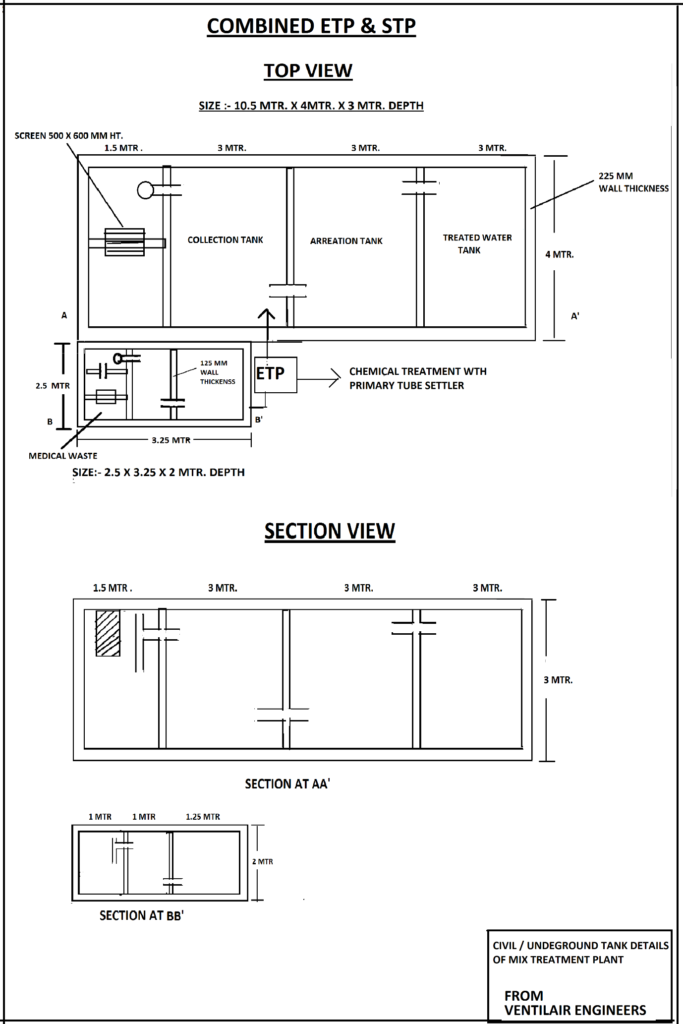

Our Hybrid Effluent Treatment Plant is a multi-stage system combining physio-chemical, biological, and tertiary treatment technologies for maximum efficiency and regulatory compliance:

- physio-Chemical Treatment

- Coagulation & Flocculation

- pH Adjustment & Neutralization

- Primary Settling (Lamella Settlers or Clarifiers)

- Biological Treatment

- ASP or MBBR systems to reduce BOD/COD

- Aeration tanks with fine bubble diffusers

- Sludge handling and stabilization

- Tertiary/Polishing Stage (Optional)

- Ozonation or ACF for odor, color, and chemical residue removal

- Ultra Filtration (UF) or Membrane Polishing where required

- Final output compliant with CPCB/SPCB norms and ZLD-ready

Why Choose VEPL for Leather Industry ETPs?

- Custom-Engineered Designs tailored to specific raw effluent loads

- Integrated Hybrid Systems for organic + inorganic contaminant removal

- Scalable Solutions for small, medium, and large-scale tanneries

- Compliance-Driven Approach supporting ZLD (Zero Liquid Discharge) if required

- In-House Manufacturing & Fabrication with FRP-coated MS structures for durability

- Complete Instrumentation: Flow meters, pH/ORP sensors, chemical dosing, and automation options (PLC/SCADA/IoT)

Applications

- Chrome & Vegetable Tanning Units

- Leather Dyeing and Finishing Units

- Individual and Combined CETP Systems

- Sludge Treatment & Heavy Metal Recovery

Certifications & Industry Approvals

- ISO Certified

- GEM Registered Vendor

- CPWD Approved

- NSIC & MSME Certified

Proven Track Record in India & Abroad

Ventilair Engineers has successfully installed ETPs for numerous tanneries, both in India and internationally. Our plants have consistently helped clients meet environmental discharge norms while optimizing operational costs and enabling reuse of treated water in non-potable processes.