MBBR Sewage Treatment System (Moving Bed Biofilm Reactor)

Advanced Biological Wastewater Treatment Technology

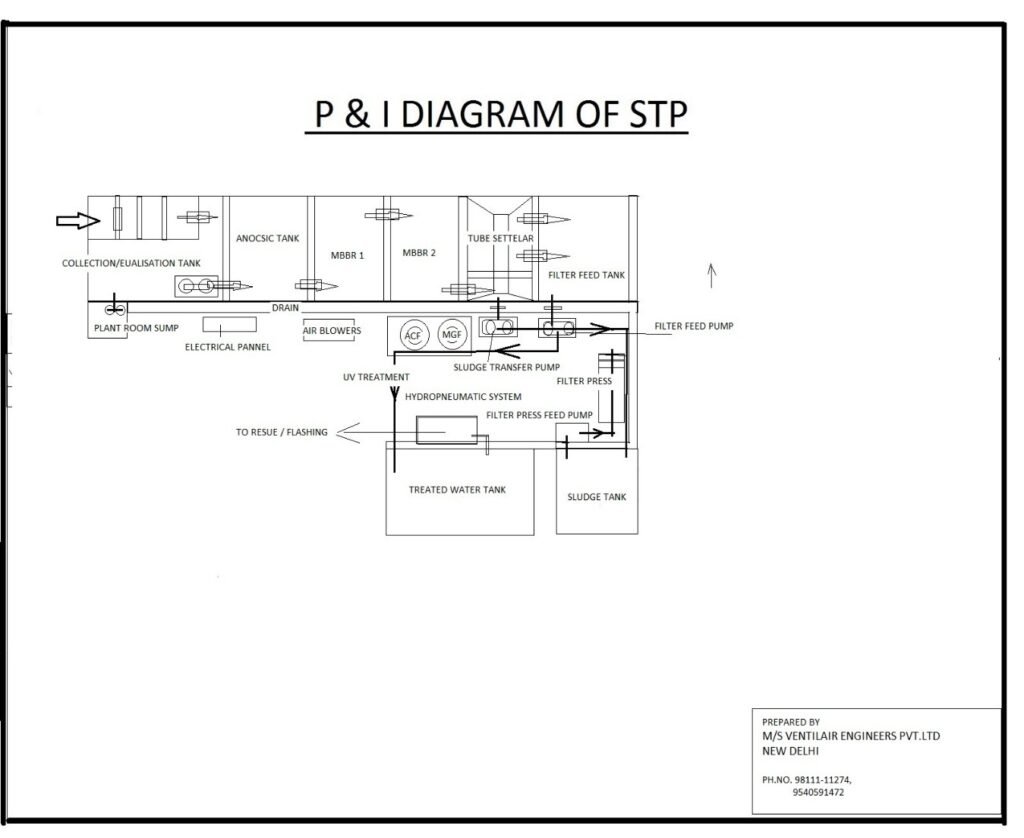

VEPL’s MBBR Sewage Treatment Plant is an advanced biological solution engineered to treat domestic and industrial wastewater with high efficiency, low footprint, and minimal maintenance. Utilizing specially designed biofilm carriers suspended in the aeration tank, the MBBR process ensures optimal microbial growth and superior organic load reduction.

Product Description

The MBBR (Moving Bed Biofilm Reactor) system combines the benefits of activated sludge and fixed-film systems. It is ideal for handling fluctuating loads, high BOD/COD concentrations, and decentralized sewage treatment applications.

Our MBBR system is scalable, modular, and customized based on inflow parameters and site conditions. It can be integrated into new plants or retrofitted into existing ones.

Technical Specifications

Parameter | Specification |

Treatment Capacity | 1 KLD to 5 MLD (customized as per need) |

Technology | Moving Bed Biofilm Reactor (MBBR) |

Carrier Media Type | High surface area polyethylene media |

Aeration System | Fine bubble diffused aeration |

Media Fill Ratio | 30–70% of tank volume |

Retention Time | 6–8 hours (depending on load) |

Material of Construction | RCC, MSEP, FRP, HDPE (as per requirement) |

Power Requirement | 1–10 HP (depending on plant size) |

Control Panel | Semi-automatic / PLC-based |

Installation Type | Above ground / Underground |

Inlet & Outlet Water Quality Parameters

Primary Treatment Stage (After Screening & Grit Removal)

Parameter | Inlet Range | Outlet Range |

pH | 6.5 – 8.5 | 6.5 – 8.5 |

BOD | 250 – 400 mg/L | 150 – 200 mg/L |

COD | 500 – 700 mg/L | 300 – 450 mg/L |

TSS | 200 – 350 mg/L | 100 – 150 mg/L |

Oil & Grease | 20 – 50 mg/L | < 20 mg/L |

Secondary Treatment Stage (MBBR Reactor + Clarifier)

Parameter | Inlet Range | Outlet Range |

BOD | 150 – 200 mg/L | < 30 mg/L |

COD | 300 – 450 mg/L | < 100 mg/L |

TSS | 100 – 150 mg/L | < 30 mg/L |

Ammonia (NH4) | 20 – 40 mg/L | < 10 mg/L |

Tertiary Treatment Stage (Filtration + Disinfection)

Parameter | Inlet | Outlet |

BOD | < 30 mg/L | < 10 mg/L |

COD | < 100 mg/L | < 30 mg/L |

TSS | < 30 mg/L | < 5 mg/L |

Pathogens | Present | Removed (99%) |

Color/Odor | Mild | Removed |

Ultrafiltration (UF) – Final Polishing

Parameter | Inlet | Outlet |

BOD | < 10 mg/L | < 5 mg/L |

TSS | < 5 mg/L | < 1 mg/L |

Turbidity | < 5 NTU | < 1 NTU |

Pathogen Removal | Partial | 99.99% (Sterile) |

Water Reuse | Irrigation, Toilet, Cooling | ✅ |

Applications

- Residential Societies & Apartments

- Hotels & Resorts

- Commercial Buildings

- Industrial Parks

- Hospitals & Institutions

- Municipal Sewage Projects

Key Features

- Compact footprint, easy to install & expand

- Fully automated operation with low manpower

- High resistance to shock loads

- Reduced sludge generation

- Energy efficient aeration

- Suitable for reuse & zero liquid discharge (ZLD)