Nano Etp & Waste Water Filtration Unit

Environment is the mixture of our life source, as we know that we are made from five elements i.e., Ether (Akash), Wind (Vayu), Fire (Agni), Earth (Prithvi), Water (Jal). All elements contain the equal importance in our life.

Water is Precious so we work with this Aim- (SAVE, TREAT & REUSE WATER)

Now-a-days the “GOVERNMENT & NGT” is very strict towards the usage and drainage of water due to the scarcity. After the strictness of government, all industries are facing a big problem (Who use water in their commercial work). To discharge the water “CPCB” want to drain the water at given fixed norms but, a small company cannot spend lot of money on this. Keeping in mind the problem of small industries, we have worked out a solution for them, especially for AUTOMOBILE (car washing) and PLASTIC DANA INDUSTRY, who use the small amount of water and are obliged to reuse water again.

We want to describe our both the new products, which are small and specially designed & manufactured for the small industry or for the small amount of water.

- We have launched a product “NANO ETP”, which is effective and impressive for all kind of small It is a complete ETP, based on manual Physico-chemical method with continuous flow. Water flow rate will be 400 ltr/h. We are giving you a complete ETP in low cost, effective for treating the water, which would be reused in industrial process and horticulture. It is a packaged & skid mounted type ETP in an Exciting Fix starting price 175000/-.

- “Waste water filtration unit” is a simple effluent filtration unit start under one lakh Fix price, which is SKID MOUNTED, able to remove mud, oil & grease, within a limit of BOD & TSS which is given in the quotation sheet. It can be used in Automobile and Plastic Dana manufacturing industries, process is just Save, Treat & Reuse Water.

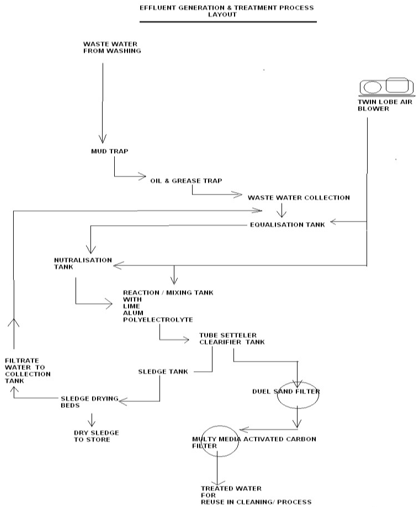

"NANO” ETP

|

S.NO. |

DESCRIPTION |

QTY. |

SIZE |

MADE |

SCOPE |

|

1 |

Screen Chamber With screen |

1No. |

600 x 600 x 600 mm Depth |

Brick Work |

Client’s Scope |

|

2 |

Mud Trap |

1No. |

1000 x 1000 x 1800 mm Depth |

Brick Work |

Client’s Scope |

|

3 |

Oil & Grease Trap |

1No. |

1000 x 1000 x 1000 mm Depth |

Brick Work |

Client’s Scope |

|

4 |

Collection Tank |

1No. |

1000 x 2000 x 1800 mm Depth |

Brick Work |

Client’s Scope |

|

5 |

Equalization Tank |

1No. |

1000 x 2000 x 1800 mm Depth |

Brick Work |

Client’s Scope |

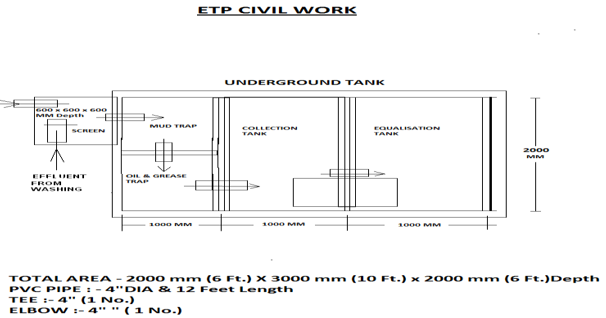

CIVIL WORK FOR SKID MOUNTED NANO ETP (400 LTRS. /HOUR) PLATFORM FOR SKID OVER THE TANK -2000 MM X3000 MM X 2000 MM HT.

ETP SKID – 12OO MM X 2000 MM LENGTH

CIVIL WORK FOR SKID MOUNTED NANO ETP (400 LTRS. /HOUR) PLATFORM FOR SKID OVER THE TANK -2000 MM X3000 MM X 2000 MM HT.

ETP SKID – 12OO MM X 2000 MM LENGTH

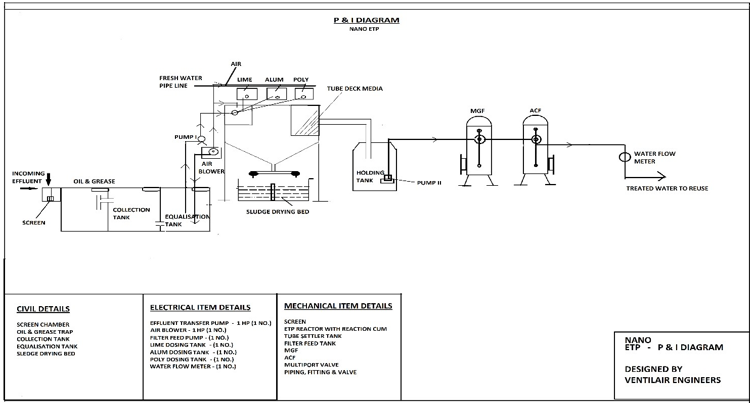

CIVIL WORK DIAGRAM

SKID MOUNTED NANO ETP

Design, Supplying, Installing, Testing & Commissioning of Effluent Treatment Plant capacity 400 LTRS. PER HOUR

Nature of effluent – Industrial waste, washing waste water etc.

Daily average flow Trade effluent

|

pH |

6 – 8 |

|

|

TSS |

250 |

400 Mg/ L |

|

BOD5 |

200 |

300 Mg/L |

|

COD |

250 |

400 Mg/L |

|

Oil & Grease |

40 |

50 Mg/L |

Effluent discharge standards after treatment

|

pH |

6.5 – 9 |

|

BOD5 |

Less than 100 Mg/L |

|

TSS |

Less than 100 Mg/L |

|

COD |

Less than 150 Mg/L |

|

Oil & Grease |

Less than 5 Mg/L |

Skid Mounted Nano Effluent Treatment Plant shall include the following items:

Daily average flow Trade effluent

Mud Chamber Screen

with Frame,

Settling / Clarifier Tank with Ladder

Clear Water Tank

Filtration through MGF & ACF

Effluent transfer pump

Filter feed pump

Air Compressor

Sledge Drying Bed

Piping, valves etc

Dosing Tanks

Rota Meter

Electrical MCB Box

EXCLUSION

Ø Design of civil tanks – structures and

preparation of RCC structural drawings, civil BOQ etc.

Ø All civil works including grading / levelling of site foundations, building drains, pipe and underground cable trenches, grouting, platforms and staircase for equipment pipe supports, inserts, puddle pipes, structural supports for air grids & pipes.

Ø Unloading and safe storage of equipment at site.

Ø Construction roads inside the plant and approach roads. Ø Construction of fencing of the plant.

Ø Utilities e.g., Water, Electricity etc.

Ø Supply of all types of laboratory equipment. Ø Electrification and area illumination.

Ø Emergency power supply and illumination system.

Ø All piping, cabling etc. beyond the termination points as mentioned in our offer. Ø Lightening protection.

Ø Operation & Maintenance of the plant.

Ø Commissioning consumables, chemicals, lubricants etc. Ø NOC/Approval from Statutory Bodies.

Ø Any other item not specifically mentioned in our scope.

SCOPE OF WORK:

- Design and submission of drawings

- Supply of all the mechanical equipment

- Supply of required electrical MCB

- Erection of all the mechanical equipment of ETP

BENEFITS OF NANO ETP: -

SEMI – AUTOMATIC UNIT

LOW-COST PRODUCT ONLY Rs. 175000 INR LESS FOOT PRINT (SPACE SAVING) CONTINIOUS FLOW UNIT

RECYCLING UNIT

MAXIMUM PLANT IN M.S WITH FRP LONG LASTING DURABIULTY

READY TO INSTALL

FLOW RATE – 400 LTRS. PER HOUR

EFFECTIVE TO TREATING INDUSTRIAL WASTE WATER PACKAGED & SKID MOUNTED TYPE

EASY TO OPERATE EASY TO MOVE

HUSTLE FREE INSTALLATION LITTLE MAINTENANCE EXCELLENT RESULT

PRICELIST WITH MODEL OF NANO PLANT (400L/HOUR)

|

1 |

NANO ETP & BIOLOGICAL |

VE/M/NETP/1 |

179999 |

|

VE/S/NETP/2 (WITHOUT SKID) |

229888 |

||

|

VE/M/NSETP/3 (WITHOUT DOSING PUMP) |

229888 |

||

|

VE/S/NSETP/4 |

259999 |

||

|

|

|

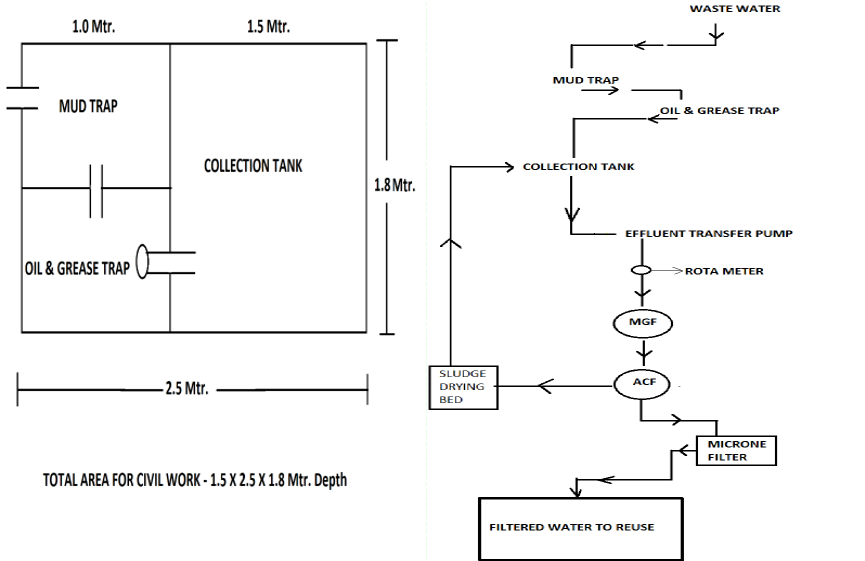

WASTE WATER FILTRATION UNIT

CIVIL WORK FOR SKID MOUNTED WASTE WATER FILTRATION UNIT (1000L/HOUR)

|

1 |

Mud Trap Chamber |

1 No. |

1.0 x 1.0 x 1.0 Mtr. Depth |

Client’s Scope |

|

2 |

Oil & Grease Trap Chamber |

1 No. |

1.0 x 1.0 x 1.0 Mtr. Depth |

|

|

3 |

Collection Tank |

1 No. |

2.0 x 2.0 x 1.8 Mtr. Depth |

|

|

4 |

Sludge Drying Bed |

1 No. |

1.0 x 1.5 x 0.5 Mtr. Ht. |

Skid Mounted Effluent Filtration Unit shall include the following items:

Screen Chamber with Screen (Civil Work)

Screen Chamber with Mud Trap Chamber, Oil & Grease Trap Chamber, Collection Tank Filtration through MGF & ACF

Skid with Frame

Big Blue Filter

Filter Feed Pump

Air Blower

Rota Meter

Sledge Drying Beds (Civil Work) Piping, valves etc.

Electrical MCB Box

SCOPE OF WORK:

- Design and submission of drawings

- Supply of all the mechanical equipment

- Supply of required Electrical MCB

- Erection of all the mechanical equipment of

CIVIL WORK, LAYOUT & P & I DRAWING OF FILTRATION UNIT

EXCLUSION

Ø Design of civil tanks – structures and preparation of RCC structural drawings, civil BOQ etc. Ø All civil works including grading / levelling of site foundations, building drains, pipe and underground cable trenches, grouting, platforms and staircase for equipment pipe supports, inserts, puddle pipes, structural supports for air grids & pipes.

Ø Unloading and safe storage of equipment at site.

Ø Construction roads inside the plant and approach roads. Ø Construction of fencing of the plant.

Ø Utilities e.g. Water, Electricity etc.

Ø Supply of all types of laboratory equipment. Ø Electrification and area illumination.

Ø Emergency power supply and illumination system.

Ø All piping, cabling etc. beyond the termination points as mentioned in our offer. Ø Lightening protection.

Ø Operation & Maintenance of the plant.

Ø Commissioning consumables, chemicals, lubricants etc. Ø NOC/Approval from Statutory Bodies.

Ø Any other item not specifically mentioned in our scope.

SPECIALITY OF FILTRATION UNIT: –

- Low-cost product only 99999 INR (START)*

- Skid Mounted Filtration unit

- Flow up to 500ltr/hr to 1000ltr/hr

- ZLD treatment method

- Less electricity used

- No chemicals used

- No recuing expenditure

- Easy to operate

- Automation arrangement

- Hustle free installation

- Easy to move

- Excellent result

PRICELIST WITH MODEL OF FILTRATION PLANT (1000L/HOUR)

|

2 |

FILTRATION UNIT |

VE/FRP/EFU/1 |

99999 |

|

VE/MS/EFU/2 |

150000 |

||

|

VE/FRP/BEFU/3 |

125000 |

||

|

VE/MS/BEFU/4 |

175000 |

||

|

|

|

INSTALLATION, FREIGHT & GST EXTRA