Rice Mill Effluent Treatment Solutions

Understanding the Challenge: Industry-Specific Effluent Complexity

Effluent Treatment is not a one-size-fits-all solution. At Ventilair Engineers Pvt. Ltd. (VEPL), we treat Effluent Treatment Plant (ETP) design as a knowledge-intensive and case-specific discipline, guided by one critical parameter—wastewater quality.

Every industry, and often every plant within an industry, generates unique effluent characteristics. Therefore, before proposing any solution, VEPL mandates a comprehensive water quality analysis from an accredited laboratory. Only then can we determine the most suitable treatment pathway—physio-Chemical, Biological, or a Hybrid System.

Rice Mill Wastewater: A Special Case

Rice milling, especially when comparing raw rice to parboiled rice processing, produces widely varying wastewater in terms of:

- BOD (Biochemical Oxygen Demand)

- COD (Chemical Oxygen Demand)

- TSS (Total Suspended Solids)

- Oil & Grease

- Color, Odor, and pH variability

These differences necessitate a specialized approach to treatment.

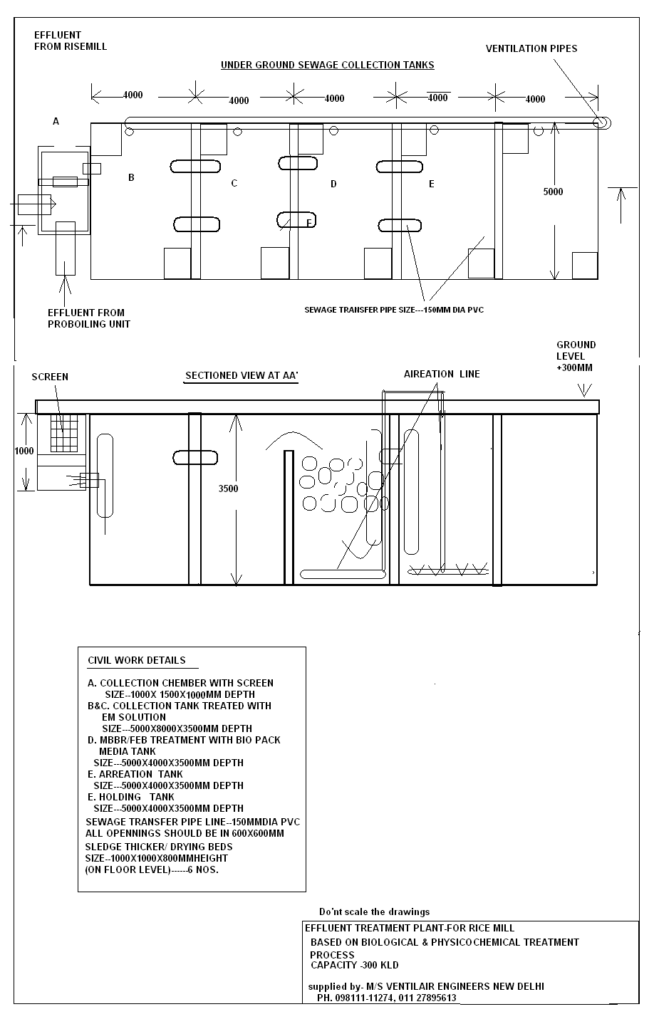

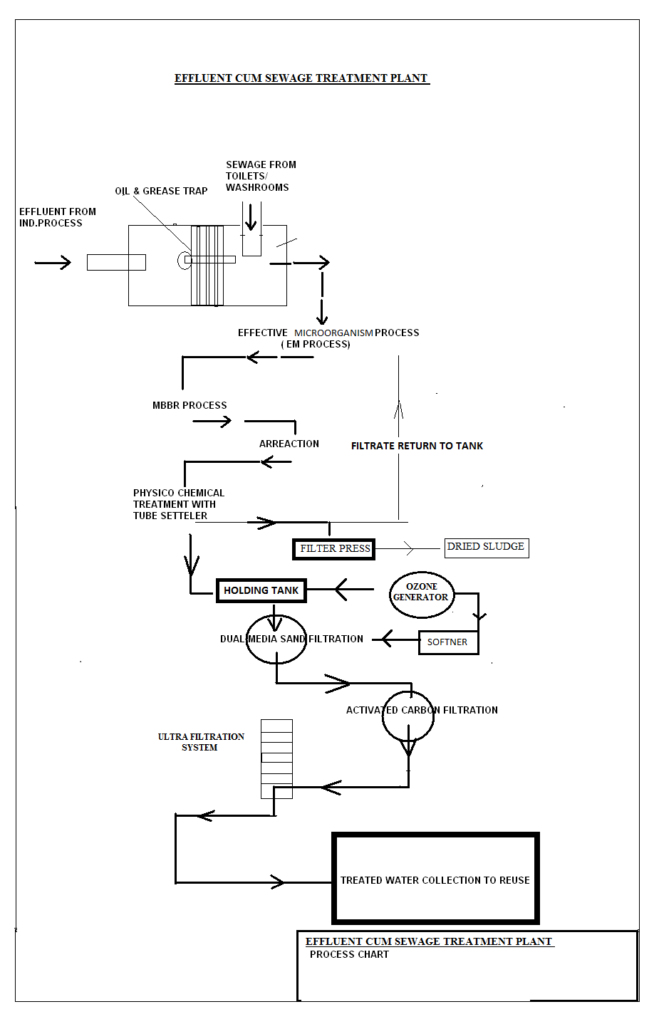

VEPL’s Innovation: Hybrid Effluent Treatment Plant (H-ETP)

To address the complexities of rice mill effluent, VEPL has developed and implemented the Hybrid Effluent Treatment Plant (H-ETP) — a proprietary solution that combines:

- physio-Chemical Treatment

- Biological Treatment

- Optional advanced tertiary steps like Ozonation, Reed Bed Systems, and Polishing Units

This integrated multi-stage approach ensures high efficiency in reducing BOD, COD, and TSS levels, even under extreme conditions. We refer to this system as a Mix Biological & Combined Treatment Plant, or more commonly as our Biological ETP Hybrid Model.

Why Choose VEPL for Rice Mill ETPs?

- Over 20 years of ETP expertise across industrial sectors

- Customized Hybrid ETPs for raw and parboiled rice mills

- In-house design, engineering, and commissioning

- Proven results for extreme BOD/COD reduction

Integration of eco-friendly & energy-efficient technology