VEPL Compact Sewage Treatment Plant for Villas & Small Housing Units

MBBR-Based | Plug-and-Play | Low-Maintenance | Fully Accessorized

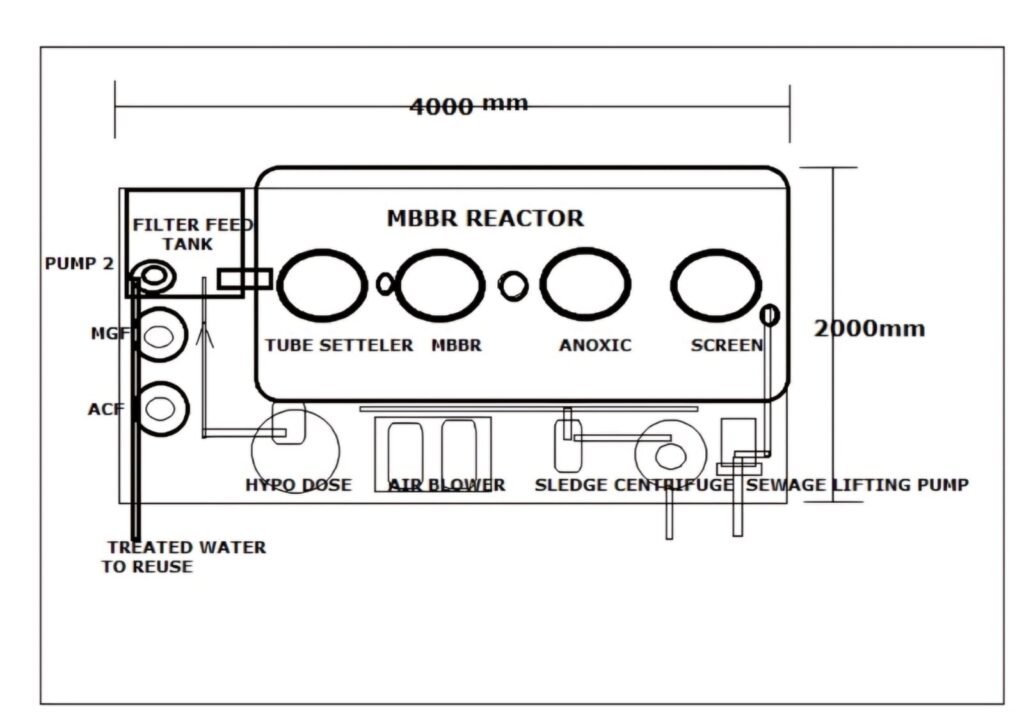

The VEPL Small-Capacity STP is a compact, prefabricated, and plug-and-play sewage treatment solution designed for individual villas, small gated communities, and low-density residential clusters. It uses Moving Bed Biofilm Reactor (MBBR) technology, ideal for domestic sewage with variable load.

The plant provides complete treatment – primary, secondary, tertiary, and ultrafiltration, along with filter press, UV disinfection, ozonator, chlorine & poly dosing, and redundant pumps and blowers (1 working + 1 standby) for operational reliability.

Technical Specifications:

Parameter | Specification |

Brand | VEPL |

Design | Modular / Compact / Skid-Mounted |

Technology | MBBR (Moving Bed Biofilm Reactor) |

Material of Construction | MS Epoxy Coated / FRP / SS Internals (as applicable) |

Capacity Range | 1 KLD to 20 KLD |

Power Supply | 230V or 415V, 1-Phase/3-Phase, 50 Hz |

Automation | Semi-Automatic / Optional PLC Control |

Pump & Blower Setup | 1 Working + 1 Standby for all critical equipment |

Footprint | 3–5 m² (varies with capacity) |

Included System Components:

Primary Treatment:

- Bar Screen Chamber (for debris removal)

- Oil & Grease Trap (optional, for kitchen wastewater)

- Equalization Tank with Air Agitation

- Poly Dosing Unit (for enhanced settling/flocculation)

Secondary (Biological) Treatment:

- MBBR Aeration Tank with bio-media

- Fine Bubble Diffusers

- Air Blower – Oil-free (1 Working + 1 Standby)

- Tube Settler / Secondary Clarifier

- Return Sludge Pump (1 Working + 1 Standby)

Tertiary Treatment:

- Pressure Sand Filter (PSF)

- Activated Carbon Filter (ACF)

- Chlorine Dosing Unit – Sodium Hypochlorite-based

- Ultra Violet (UV) System – Disinfection chamber

- Ozonator Unit – Optional, for additional polishing

Ultrafiltration (UF) Module:

- UF Membrane (Hollow Fiber, 0.01–0.1 µm)

- UF Backwash Pump (1 Working + 1 Standby)

Sludge Handling:

- Sludge Holding Section / Chamber

- Sludge Transfer Pump (1 Working + 1 Standby)

- Filter Press (Manual or Semi-Auto) for dry sludge discharge

Instrumentation & Control:

- MCC/PLC Panel (IP55 or higher, with indicators/alarms)

- Flow Meters, Level Sensors, Pressure Gauges

- Piping, Valves, Access Points

- Optional remote monitoring (IoT-based)

Inlet and Outlet Parameters:

Parameter | Raw Sewage (Inlet) | After Tertiary Treatment | Final (Post UF, UV, Ozone) |

pH | 6.5 – 8.5 | 6.8 – 8.2 | 6.8 – 8.2 |

BOD (mg/L) | 250 – 350 | < 10 | < 5 |

COD (mg/L) | 500 – 600 | < 30 | < 10 |

TSS (mg/L) | 200 – 300 | < 10 | < 5 |

Turbidity (NTU) | 100 – 150 | < 5 | < 1 |

Oil & Grease (mg/L) | 10 – 20 | < 5 | < 1 |

Pathogens (E. Coli etc.) | Present | Significantly Reduced | Nil |

Color / Odor | Foul | Removed | Colorless, odorless |

Treated water complies with CPCB norms and is suitable for:

- Flushing

- Gardening/Landscaping

- Floor washing

- Car washing

Advantages for Villa Applications:

- Small Footprint – Ideal for backyards, basements, or common utility zones

- High-Quality Recycled Water – Reduces fresh water usage

- Silent & Odor-Free – Suitable for residential areas

- Redundant Design – All pumps and blowers in 1W + 1S setup

- Low Maintenance – Easy operation with optional automation

- Energy-Efficient – Optimized for small, decentralized systems

Factory-Fabricated – Easy to install, minimal civil work