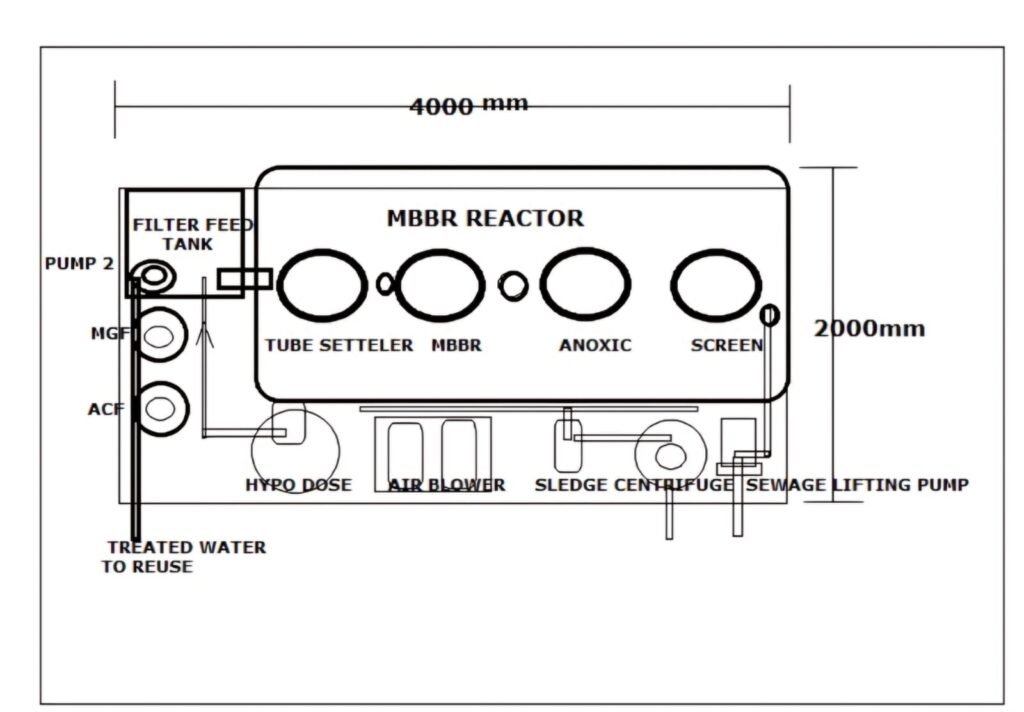

VEPL – Plug & Play STP (MSFRP Capsule-Type Sewage Treatment Plant)

A Next-Generation Overground STP System with Advanced MBBR + Filtration Technology

Ventilair Engineers Pvt. Ltd. (VEPL) introduces an innovative and uniquely engineered Plug-and-Play Sewage Treatment Plant (STP) – a Capsule-Type MSFRP (Mild Steel with FRP Coating) system that is superior to traditional FRP capsules. This over-the-ground STP unit comes pre-fabricated, pre-wired, and pre-tested, offering rapid deployment, low maintenance, and high performance for small to mid-sized establishments.

Unlike standard FRP capsules, VEPL’s MSFRP capsule is more robust, corrosion-resistant, and fully integrated with multi-stage treatment that includes settling, MBBR biological treatment, multi-grade filtration (MGF), activated carbon filtration (ACF), and sludge management with filter press. Ultrafiltration (UF) is also available as an on-demand final polishing stage.

Technical Specifications

Feature | Specification |

Design Type | Overground Pre-Fabricated MSFRP Capsule-Type |

Technology | Settling + MBBR + MGF + ACF + Optional UF |

Capacity Range | 1 KLD – 100 KLD |

Installation | Plug & Play – Ready to install with minimal site prep |

Material | MSFRP (Mild Steel + FRP-Lined Body) |

Automation | Manual / Semi-Automatic / Fully Automatic |

Power Supply | 230V / 415V, 1-phase/3-phase as per size |

Odor Control | Integrated Activated Carbon Vent System |

Sludge Handling | Filter Press or Sludge Drying Bed |

Disinfection | UV / Chlorine |

Optional Add-ons | Ultrafiltration (UF), IoT Monitoring, Solar Backup, Skid Mounting |

Compliance | CPCB / SPCB Standards for Water Reuse |

Inlet & Outlet Water Parameters – Stage-Wise Breakdown

- Primary Treatment

(Screening → Oil & Grease Trap → Settler Tank)

Parameter | Raw Sewage (Inlet) | After Primary Treatment |

BOD | 250–400 mg/L | 150–200 mg/L |

COD | 500–700 mg/L | 300–450 mg/L |

TSS | 200–350 mg/L | 100–150 mg/L |

pH | 6.5 – 8.5 | 6.5 – 8.5 |

- Secondary Treatment (MBBR Technology)

(Biofilm Reactor + Tube Settler)

Parameter | After Primary | After Secondary Treatment |

BOD | 150–200 mg/L | < 30 mg/L |

COD | 300–450 mg/L | < 100 mg/L |

TSS | 100–150 mg/L | < 30 mg/L |

- Tertiary Treatment

(MGF + ACF + UV/Chlorination)

Parameter | After Secondary | After Tertiary Treatment |

BOD | < 30 mg/L | < 10 mg/L |

COD | < 100 mg/L | < 30 mg/L |

TSS | < 30 mg/L | < 5 mg/L |

Odor & Color | Present | Odorless, Colorless |

- Optional Ultrafiltration (UF) Stage

(Final Polishing for Water Reuse in Flushing, Gardening, Cooling, etc.)

Parameter | After Tertiary | After UF Output |

BOD | < 10 mg/L | < 5 mg/L |

TSS | < 5 mg/L | < 1 mg/L |

Turbidity | < 5 NTU | < 1 NTU |

Pathogen Removal | > 99% | > 99.99% |

Key Benefits of VEPL Plug & Play Capsule STP

- Next-Gen MSFRP Design – Stronger & longer life than standard FRP systems

- Over-the-Ground Installation – No excavation required

- Rapid Deployment – Commissioned within 2–5 days

- Compact & Aesthetic – Ideal for space-constrained sites

- Fully Integrated System – Includes sludge, disinfection & filtration modules

- Zero Odor & Noise – Quiet and environment-friendly operation

- Custom Add-ons – UF, IoT-based monitoring, solar integration, etc.

- Designed for 100% Reuse – Complies with all environmental norms

Ideal Applications

- Residential Apartments & Villas

- Hotels, Resorts & Guest Houses

- Hospitals & Clinics

- Schools, Colleges & Hostels

- Commercial Buildings & Malls

- Small Factories & Food Outlets

- Farmhouses & Remote Sites

Why Choose VEPL?

- Over 1500+ STP/ETP installations across India

- Turnkey Expertise – Design → Fabrication → Installation → AMC

- Pre-fabricated systems delivered anywhere in India or abroad

- CPCB/SPCB approved & environmentally compliant

- Customization available for capacity, shape & automation level