VEPL – Zero Discharge MBBR STP Plant

(100% Reuse Without Evaporation – Based on MBBR Technology)

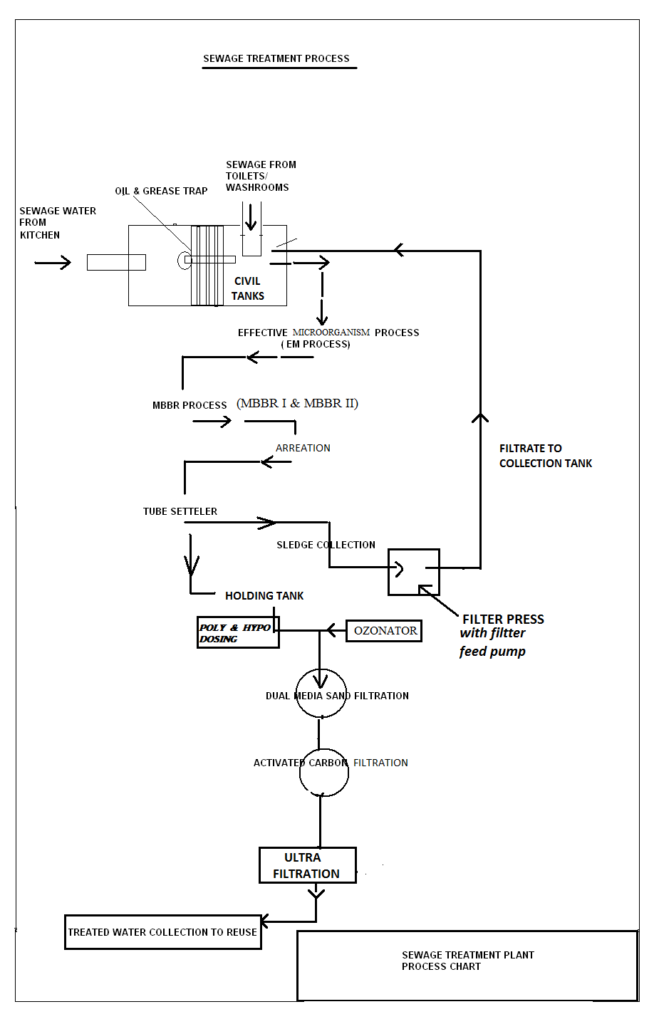

Ventilair Engineers Pvt. Ltd. (VEPL) proudly presents its advanced Zero Discharge STP Plant using MBBR (Moving Bed Biofilm Reactor) technology, designed for 100% wastewater reuse without relying on evaporation or external disposal. This compact, modular, and automated sewage treatment system ensures zero liquid discharge (ZLD) and is ideal for urban complexes, commercial buildings, industries, hostels, and institutions.

By combining biological MBBR treatment, filtration, and ultrafiltration/polishing, this STP guarantees complete water recycling for applications like toilet flushing, gardening, HVAC, and cleaning, while meeting CPCB/SPCB standards.

Technical Specifications

Feature | Specification |

Treatment Technology | MBBR (Moving Bed Biofilm Reactor) |

Discharge Type | 100% Reuse – Zero Discharge (ZLD without evaporation) |

Capacity Range | 1 KLD to 500 KLD |

Construction Type | RCC / MSEP / FRP / Underground or Containerized |

Final Water Use | Flushing, Gardening, Floor Washing, HVAC, Vehicle Washing |

Power Consumption | Low (energy-efficient blowers and pumps) |

Automation | Manual / Semi-Automatic / Fully Automatic |

Disinfection | UV / Chlorination |

Optional Polishing | UF / Activated Carbon Filter / Sand Filter |

Odor Control | Yes (biological & carbon filters) |

Compliance | CPCB / SPCB / MoEF / LEED / GRIHA |

Inlet & Outlet Parameters – Stage Wise

- Primary Treatment

(Screening ➝ Oil & Grease Removal ➝ Equalization ➝ Settling)

Parameter | Inlet (Raw Sewage) | After Primary Treatment |

BOD | 250–400 mg/L | 150–200 mg/L |

COD | 500–700 mg/L | 300–450 mg/L |

TSS | 200–350 mg/L | 100–150 mg/L |

Oil & Grease | 20–40 mg/L | <20 mg/L |

pH | 6.5 – 8.5 | 6.5 – 8.5 |

- Secondary Treatment (MBBR Process)

(Biological Treatment Using Biofilm Media + Tube Settler)

Parameter | After Primary | After Secondary Treatment |

BOD | 150–200 mg/L | < 30 mg/L |

COD | 300–450 mg/L | < 100 mg/L |

TSS | 100–150 mg/L | < 30 mg/L |

Ammonia | 10–25 mg/L | < 10 mg/L |

- Tertiary Treatment

(Pressure Sand Filter + Activated Carbon Filter + UV/Chlorination)

Parameter | After Secondary | After Tertiary Treatment |

BOD | < 30 mg/L | < 10 mg/L |

COD | < 100 mg/L | < 30 mg/L |

TSS | < 30 mg/L | < 5 mg/L |

Pathogens | Moderate | > 99% Removal |

Odor/Color | Minimal | Clear & Odor-Free |

- Final Polishing (UF/Reuse)

(Optional Ultrafiltration or Polishing Filter for Direct Reuse)

Parameter | After Tertiary | Recycled Water Output |

BOD | < 10 mg/L | < 5 mg/L |

TSS | < 5 mg/L | < 1 mg/L |

Turbidity | < 5 NTU | < 1 NTU |

Pathogen Count | 99% | Up to 99.99% Removal |

Reuse Type | Safe for Non-Potable Use (Toilets, Gardening, etc.) |

Key Benefits of VEPL’s MBBR-Based Zero Discharge STP

- 100% Water Reuse – No Evaporation, No Drain Required

- Compact Footprint – Modular & space-saving design

- Low Maintenance – Energy-efficient, biofilm-based technology

- Odor-Free, Silent & Reliable Operation

- Meets CPCB/SPCB Reuse Norms

- Ideal for Residential, Commercial, Institutional & Industrial Sites

- Expandable – Easily scalable with additional modules

- Turnkey Solution: Design ➝ Installation ➝ AMC

Ideal Applications

- Apartments, Villas, and Gated Communities

- Hotels, Malls, Shopping Complexes

- Commercial Offices & Tech Parks

- Industries & Warehouses

- Schools, Colleges, Hostels

- Hospitals, Resorts, Government Buildings

Why Choose VEPL?

- 1500+ STP/ETP Installations Across India

20+ Years of Experience in Wastewater Engineering

- End-to-End Solutions – Civil + Mechanical + AMC

- Experts in ZLD, MBBR, SBR, MBR & Plantation-Based STPs

- Export-Ready Modular Systems