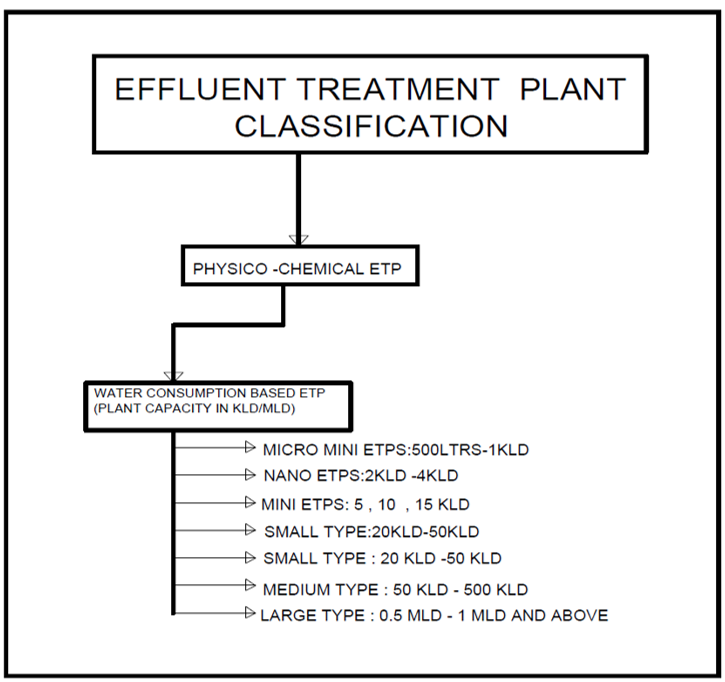

Water Consumption-Based Effluent Treatment Plants (ETPs)

Custom-Designed Systems by Ventilair Engineers Pvt. Ltd. (VEPL)

At Ventilair Engineers Pvt. Ltd. (VEPL), we understand that the volume of wastewater generated by a facility varies significantly depending on its size, operations, and water usage patterns. That’s why we offer a complete range of Effluent Treatment Plants (ETPs) designed specifically based on water consumption capacity — from as low as 2 KLD (Kilo Liters per Day) to large-scale solutions of 500 KLD and beyond.

Whether you’re a small commercial unit, medium-sized manufacturer, or large-scale industrial facility, VEPL provides perfectly tailored ETP solutions that ensure compliance, efficiency, and sustainability.

Why Design ETPs Based on Water Consumption?

Designing an ETP based on daily water consumption helps in:

- Ensuring accurate sizing of treatment components

- Avoiding underperformance or overdesign

- Reducing operating and maintenance costs

- Meeting treated water quality as per CPCB/SPCB norms

- Optimizing space, energy, and chemical usage

- Supporting treated water reuse where applicable

VEPL Water Consumption-Based ETP Models

We offer ETP systems in various capacity ranges based on the client’s daily water usage. Each plant is engineered with appropriate technology, automation level, and layout based on the load and discharge characteristics.

- 2 KLD to 10 KLD (Small-Scale Units)

Ideal for:

- Small-scale industries

- Clinics, small hospitals

- Commercial kitchens

- Retail food units, workshops

Features:

- Compact & skid-mounted design

- Manual or semi-automatic operation

- Minimal civil work required

- Easy installation & relocation

- Energy-efficient operation

Capacities:

✔ 2 KLD

✔ 5 KLD

✔ 10 KLD

- 20 KLD to 100 KLD (Medium-Scale Facilities)

Ideal for:

- Medium-sized manufacturing units

- Medium hospitals, hostels, hotels

- Agro-processing units

- Educational institutions

Features:

- Hybrid biological + physico-chemical treatment

- PLC-based automation (optional)

- Modular civil or containerized construction

- Treated water suitable for reuse (gardening, flushing)

- Online monitoring provisions available

Capacities:

✔ 20 KLD

✔ 50 KLD

✔ 100 KLD

- 100 KLD to 500 KLD+ (Large Industrial Facilities)

Ideal for:

- Large hospitals and hotels

- Pharma, chemical, leather, textile, dairy industries

- Industrial parks & CETPs

- Municipal and community applications

Features:

- Fully automatic operation with SCADA/PLC

- Advanced treatment (UF, RO, tertiary filters)

- Anaerobic + aerobic combinations (if required)

- Biogas recovery and sludge minimization options

- Online sensors, data logging, and remote access

- Designed to meet Zero Liquid Discharge (ZLD) if required

Capacities:

✔ 100 KLD

✔ 200 KLD

✔ 300 KLD

✔ 500 KLD+

Technology Selection Based on Flow Capacity

Capacity Range | Preferred Technologies | Automation Level |

2 – 10 KLD | MBBR / ASP + Settling + Filtration | Manual / Semi-auto |

20 – 100 KLD | Hybrid (Bio + Chemical) + Tertiary Filters | Semi-auto / PLC |

100 – 500 KLD+ | Anaerobic + Aerobic + Advanced Filtration | PLC / SCADA enabled |

Why Choose VEPL for Your Capacity-Based ETP?

Advantage | Description |

Experience | 25+ years in customized ETPs for every industry size |

Tailor-Made Solutions | Each system is engineered for exact flow, load, and footprint |

Reuse-Ready | Treated water can be reused for flushing, gardening, or cooling |

End-to-End Services | Design, manufacturing, installation, AMC, O&M — all under one roof |

CPCB/SPCB Compliance | Guaranteed BOD, COD, TSS reduction within regulatory discharge limits |

Affordable Setup | Cost-effective design with high ROI and low lifecycle cost |